B

A

B

A

4

7

3

D

C

2

1

3AUA0000101742

5

6

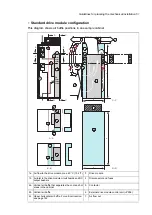

Transport package contents

With B051: Clear plastic shrouds. See below for the box contents.

1

With standard drive module configuration: Output cable connection terminals. See below for the box

contents.

2

Plywood support

3

Drive module with factory installed options and multilingual residual voltage warning sticker, top guide

plate, pedestal guide plate, telescopic ramp package, fastening screws in a plastic bag, control unit options,

delivery documents, printed multilingual installation and start-up quick guide. Other printed manuals if

ordered.

4

Ramp box. With H370: also input cable connection terminals box.

5

Accessories box

6

Pallet

7

Mechanical installation 57

10

Summary of Contents for ACH580-04

Page 1: ... ABB DRIVES FOR HVAC ACH580 04 drive modules Hardware manual ...

Page 2: ......

Page 4: ......

Page 54: ...54 ...

Page 88: ...88 ...

Page 100: ...100 ...

Page 118: ...118 ...

Page 122: ...122 ...

Page 124: ...124 ...

Page 128: ...3 6 5 5 128 Maintenance ...

Page 134: ...134 ...

Page 156: ...R10 standard configuration 156 Dimension drawings ...

Page 157: ...R10 with E208 0H354 H356 H370 0H371 Dimension drawings 157 ...

Page 158: ...R10 with option B051 158 Dimension drawings ...

Page 159: ...R10 with option E208 H356 P906 192 Tools R10 3 1 Dimension drawings 159 ...

Page 160: ...R10 with option E208 0H371 H356 0H354 H370 P906 Tools 191 R10 2 1 160 Dimension drawings ...

Page 161: ...R10 with option B051 P906 190 Tools R10 1 1 Dimension drawings 161 ...

Page 162: ...R11 standard configuration 162 Dimension drawings ...

Page 163: ...R11 with option E208 0H371 H356 0H354 H370 Dimension drawings 163 ...

Page 164: ...R11 with option B051 164 Dimension drawings ...

Page 165: ...R11 with option E208 H356 P906 Dimension drawings 165 ...

Page 166: ...R11 with option E208 0H371 H356 0H354 H370 P906 166 Dimension drawings ...

Page 167: ...R11 with option B051 P906 Dimension drawings 167 ...

Page 186: ... Declaration of conformity 186 The Safe torque off function ...

Page 206: ...Dimension drawing 206 External control unit option P906 ...

Page 212: ...212 ...

Page 224: ...224 ...

Page 226: ...226 ...

Page 234: ...234 ...