3

CAUTION Some of the IC devices used in the DPC are static-sensitive and

may be damaged by improper handling. When adjusting or servicing the

device, use of a grounded wrist strap is recommended to prevent inadvertent

damage to the integral solid-state circuitry.

2.2

Primary Gas Connections

The DFC Mass Flow Controller will not operate with liquids. Only clean, non corrosive

gases may be introduced into the instrument. If gases are contaminated, they must be

fi ltered to prevent the introduction of impediments to the sensor.

For more information, contact your distributor or Aalborg

®

.

Prior to connecting gas lines, inspect all parts of the piping system, including ferrules and

other fi ttings, for dust or other contaminants. Do not use pipe grease or sealant on process

connections as they can contaminate narrow laminar fl ow elements that may cause perma-

nent damage to the instrument.

When connecting the gas system to be controlled, be sure to observe the direction of gas fl ow

as indicated by the arrow on the front of the instrument.

Insert tubing into the compression fi ttings until the ends of the properly sized tubing sit fl ush

against the shoulders of the fi ttings. Compression fi ttings are to be tightened 1¼ turns

according to the manufacturer's instructions. Avoid overtightening which may seriously

damage the compression fi tting.

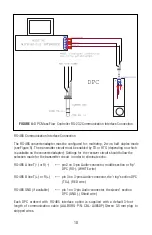

2.3

Pressure Requirements

2.3.1 DPC 07/17/37/47/57/67/77 Pressure Requirements

Maximum operating line (common mode) pressure for DPC07/17/37/47/57/67/77 series

fl ow controllers is 120 PSIG (8.3 Bar). For controllers with downstream valve confi guration

if the installation line pressure is more than 120 PSIG (8.3 Bar), a pressure regulator must

be installed upstream of the fl ow controller to bring pressure down to 120 PSIG (8.3 Bar).

CAUTION: DPC meters should not be used for monitoring oxygen gas unless

specifi cally cleaned and prepared for such application.

CAUTION: For DPC07/17/37/47/57/67/77 fl ow controllers, the maximum

common mode pressure in the instrument must not exceed 120 PSIG

(8.3 bar).Applying pressure above 120 PSIG (8.3 bar) will cause permanent

damage to the differential pressure sensor.

Summary of Contents for DPC

Page 6: ...2...

Page 120: ...116 APPENDIX I COMPONENT DIAGRAM Top Component Side...

Page 121: ...117 Bottom Component Side...