8

3D SYSTEMS, INC

.

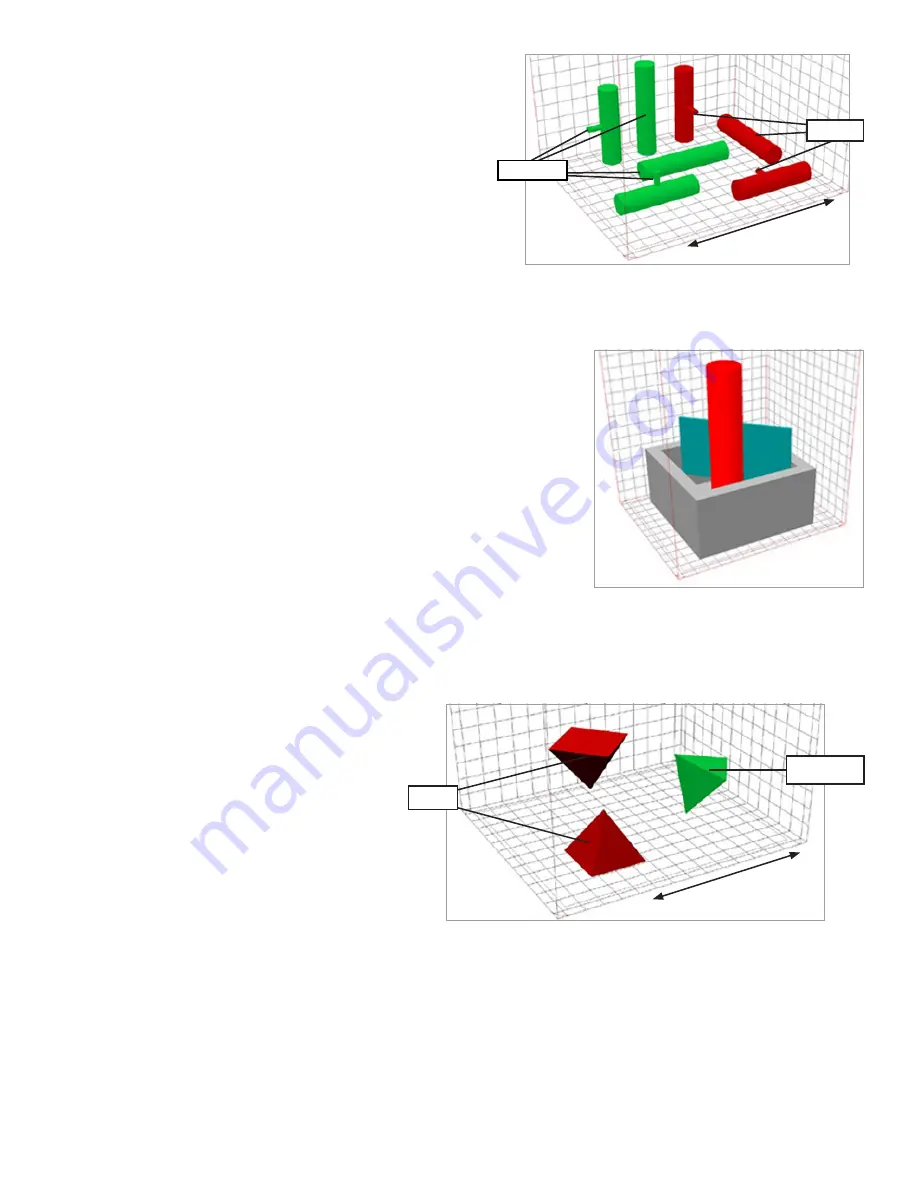

Cylinders and Holes

•

Building a cylinder horizontally is faster; but building it

vertically eliminates Z stepping on the sides of the cylinder.

•

Holes (or inside diameters of hollow cylinders) will also have a

better appearance when built in X/Y plane

•

If the cylinder has another smaller cylinder attached to it, and is

lying down, make sure that the smaller cylinder is facing in an

upward orientation.

•

If standing up, orient the smaller cylinder in the direction of the

roller.

Closed Boxes, Cylinders, and Shapes

Geometries that are closed on all but one side should be placed in the print area with the open side facing up. This reduces heat

buildup in the print cake and the part, making breakout easier and extending material life.

Nesting

You can nest smaller parts within larger ones to utilize more of the print area, as

long as the smaller parts can be removed after printing. If you nest parts, you

should maintain a minimum of 0.25 inches (6.35 mm) between the closest walls

of each part to the others. The part containing the nested parts should always be

facing with the open side up.

Triangular

Try to place the triangular shapes in the print so

that none of the three sides is perpendicular to

the direction of the roller motion, and so that the

base is not at the top in orientation. This offers less

resistance to the material as it flows across the print

bed (thus reducing the possibility of shifting) and will

result in a flatter base.

Large blocky part

Thick cross-sections that have features with X/Y slices or Z depth greater than 12.7 mm (0.5 in.) are more likely to experience

distortion. Start these demanding parts later in the build (at greater Z), after other parts have already been built underneath

Rotating the part a few degrees about X and/or Y can help to mitigate this distortion. Rotation to 30° is shown to give good

results. Along with rotating around X and Y axes, rotating around the Z axis can also help reduce distortion

Refer to the

Distortion

section for more information.

Mating Surfaces

Parts that are to be printed in more than one piece, or parts that will have mating surfaces, should always be placed such that

the mating surfaces are printed in the same orientation. It is preferable that the mating surfaces be printed facing upward for

flatness. If this is not possible, print the mating surfaces in the Z-axis. The least desirable-choice for orientation would be to

print the parts with the mating surfaces facing downward.

Preferred

Avoid

Roller Motion

Avoid

Preferred

Roller Motion

Orientation for cross sections