Zlin Aviation

Section 1

Maintenance Manual Aircraft Maintenance Manual

Issued: 01/02/2006

QAP-AMM-Rev02

Date of latest Revision: 23/01/2013

Page Number: 1-33

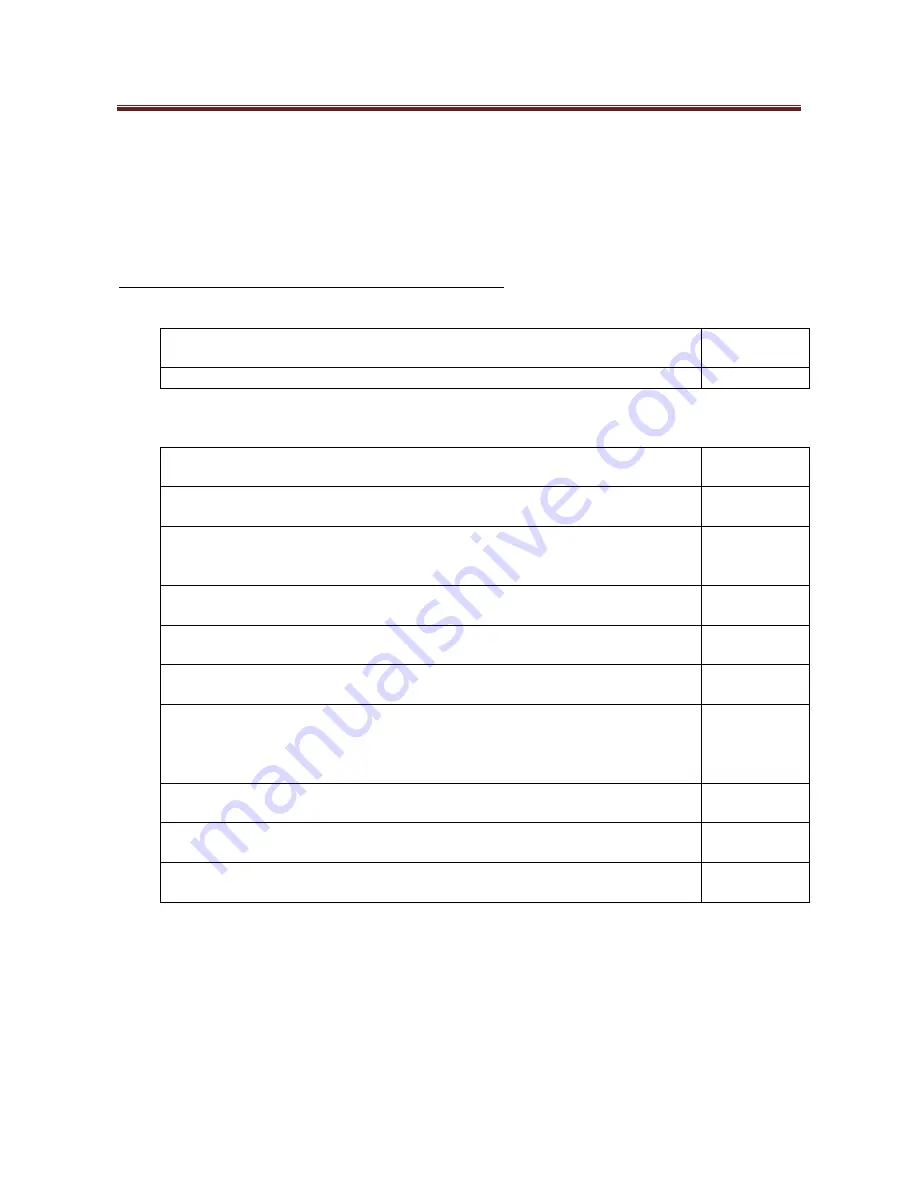

1.2.5

100 Hours or Annual Condition Inspection

(Whichever comes first)

Note:

make sure that after the inspections, aircraft is free of any tools, parts and debris, and

reinstall all access doors, fairing, seats and so on, removed for the inspection.

Complete entries in log book, or any other required records

In addition to all the inspections required at 50 hours, the following must also be inspected.

General

Level of

certification

Control log books and flying books for any records

Owner

Fuselage-Wings

1

Clean the entire aircraft and open all panels to allow access for

inspection.

Owner

2

Check aircraft external covering for rents, tears, in the fabric covered

parts.

LSRMA

3

Check windscreen and all windows for condition. Verify all glasses

correctly open and close, and ensure door hinges are in good condition.

Grease hinges.

Owner

4

Check wing support attachment pins and bolts for correct torque and

no abnormal play

LSRMA

5

Inspect wing covering, check leading and trailing edges for damage

or deformation.

LSRMA

6

Inspect aileron and flap hinges and attachments. Check attachment

pins for security and locking.

LSRMA

7

Inspect spar compression rod attachments. These attachments are

fastened with steel bolts which must be inspected for wear or corrosion.

Even in the case of minute wear, replacement must be carried out

immediately.

LSRMA

8

Check wing compression rods attachment plates for wear or

corrosion.

LSRMA

9

Verify the tail surface attachment pins and supporting struts are

secure and in good condition.

LSRMA

10

Inspect the fuselage lower beam adjacent to the tail for corrosion

damage or deformity through heavy landing.

LSRMA