035-17480-000 Rev. A (800)

22

Unitary Products Group

ADJUSTMENT OF MANIFOLD GAS PRESSURE

Manifold gas pressure may be measured by two different pro-

cedures. It may be measured with the burner box cover in

place or it may be measured with the burner box cover

removed. Follow the appropriate section, 1a or 1b in the

instructions below.

1.

Read the inlet gas pressure using either of the two meth-

ods below.

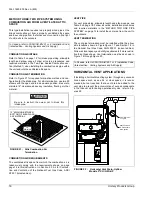

a.

Reading the gas pressure with the burner box

cover in place - Disconnect the pressure reference

hose from the right side of the burner box. Using a

tee fitting and a short piece of hose, connect the

negative side of the manometer to the burner box

pressure reference port. Connect the positive side

of the manometer to the adapter previously installed

in the gas valve ( Refer to Figure 27.)

b.

Reading the gas pressure with the burner box

cover removed - Remove the screws securing the

burner box front cover plate. Remove the cover. It is

gasketed and may stick in place. Connect the posi-

tive side of the manometer to the adapter previously

installed in the gas valve as shown in Figure 27.

There will be no second connection to the manome-

ter as it will reference atmospheric pressure.

The regulated outlet pressures, both low and high, have been

calibrated at the factory. Additional pressure adjustment

should not be necessary. If adjustment is necessary, set to

the following specifications. After adjustment, check for gas

leakage.

Low Outlet Pressure Adjustment

1.

Turn off all electrical power to the system at main fuse or

circuit breaker.

2.

Attach a manometer to the outlet pressure tap of the

valve.

3.

Turn on power and energize main and redundant (P.M.)

solenoids. Do not energize HI terminal.

4.

Remove low adjustment seal screw Figure 25 on

page 21.

5.

To increase outlet pressure, turn the 3/32” socket set

screw below the low adjustment seal screw clockwise.

To decrease outlet pressure, turn the set screw counter-

clockwise. Adjust regulator until pressure shown on

manometer matches the pressure specified on the appli-

ance rating plate.

6.

Replace low adjustment seal screw and tighten securely.

Cycle the valve several times to verify regulator setting.

7.

Remove manometer and replace the outlet pressure tap

plug.

High Outlet Pressure Adjustment

1.

Turn off all electrical power to the system at main fuse or

circuit breaker.

2.

Attach a manometer to the outlet pressure tap of the

valve.

3.

Turn on power and energize main and redundant (P.M.)

solenoids as well as the HI terminal.

4.

Remove high adjustment seal screw to expose the 3/32”

socket set screw (refer to Figure 26).

Be sure to relight any gas appliance that were

turned off at the start of this input check.

Natural Gas

Propane Gas

Low Fire

1.6 IWG

6.5 IWG

High Fire

3.5 IWG

10.0 IWG

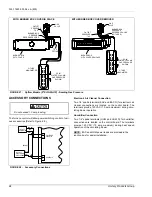

TABLE 6 : GAS RATE (CUBIC FEET PER HOUR)

SECONDS FOR ONE

REVOLUTION

SIZE OF TEST DIAL

1/2

CUBIC FOOT

1

CUBIC FOOT

10

180

360

12

150

300

14

129

257

16

113

225

18

100

200

20

90

180

22

82

164

24

75

150

26

69

138

28

64

129

30

60

120

32

56

113

34

53

106

36

50

100

38

47

95

40

45

90

42

43

86

44

41

82

46

39

78

48

37

75

50

36

72

52

35

69

54

34

67

56

32

64

58

31

62

60

30

60