035-17480-000 Rev. A (800)

Unitary Products Group

7

When the furnace is used in conjunction with a cooling coil,

the coil must be installed parallel with, or in the supply air side

of the furnace to avoid condensation in the primary heat

exchanger.

When a parallel flow arrangement is used, the dampers or

other means used to control air flow must be adequate to pre-

vent chilled air from entering the furnace, and if manually

operated, must be equipped with means to prevent operating

of either unit unless the damper is in the full heat or cool

position.

UPFLOW MODELS

Supply Plenum Connection

Attach the supply plenum to the fur-

nace outlet duct connection flanges.

This is typically through the use of S

cleat material when a metal plenum is

used. The use of an approved flexible

duct connector is recommended on all

installations. This connection should be

sealed to prevent air leakage.

If a matching cooling coil is used, it

may be placed directly on the furnace

outlet and sealed to prevent leakage.

Follow the coil instructions for installing

the supply plenum.

On all installations without a coil, a removable access panel

is recommended in the outlet duct such that smoke or

reflected light would be observable inside the casing to indi-

cate the presence of leaks in the heat exchanger. This

access cover shall be attached in such a manner as to pre-

vent leaks.

Return Duct Connection

Return air may enter the furnace through the side(s) or bot-

tom depending on the type of application. Return air may

not be connected into the rear panel of the unit. Refer to

the "Filter Installation" section of this instruction for the type of

application desired for specific installation details.

NOTE:In order to achieve the airflow indicated in the table, it

is recommended those applications over 1800 CFM use

return air from two sides, one side and the bottom or bottom

only. For single return application, see data and notes on

blower performance data tables in this manual.

FILTER INSTALLATION - UPFLOW

All applications require the use of a filter. A high velocity filter

and retainer are provided for field installation.

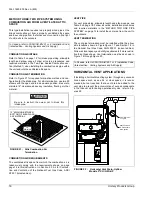

Internal Installation

1.

Select desired filter position (left/right side, and/or bot-

tom). Remove the corresponding cabinet cut-outs per

instructions provided.

2.

Install snap-in retainer clips into the corresponding slots

from the outside rear of the cabinet (Refer to Figure 2).

To prevent cabinet air leaks, install snap-in plugs (pro-

vided) into the unused slots at the outside rear of the

cabinet.

3.

Install the wire retainer inside the cabinet. Insert the

open ends of the wire retainer into the clip loops at the

rear of the blower compartment. The retainer wire should

pivot freely like a hinge, on the clips at the rear of the

cabinet. (Refer to Figure 3).

4.

Install the filter(s) provided. Cut filter if necessary to

match air opening in cabinet. Filter should extend

beyond opening edge as much as possible to prevent air

from bypassing the filter. DO NOT remove stiffening rods

from inside the filter. Shorten the rods, if necessary, to

match final filter size.

TABLE 2: UNIT CLEARANCES TO COMBUSTIBLES

(ALL DIMENSIONS IN INCHES)

All surfaces identified with the unit in an upright configuration

APPLICATION

TOP

FRONT

REAR

LEFT

SIDE

RIGHT

SIDE

FLUE

FLOOR/

BOTTOM

CLOSET

ALCOVE

ATTIC

LINE

CON-

TACT

UPFLOW MODELS (P*XU / G9D-UP)

UPFLOW

1

3

0

0

0

0

COMBUSTIBLE

YES

YES

YES

NO

FIGURE 2 :

Furnace Filter Slot Locations

FURNACE

(REAR CABINET)

RIGHT

SIDE

SLOTS

LEFT

SIDE

SLOTS

BOTTOM SLOTS

CABINET

SLOT

FILTER SUPPORT

CLIPS (PROVIDED)

PLUG UNUSED

CABINET SLOTS

WITH PLUGS

(PROVIDED)