035-17480-000 Rev. A (800)

Unitary Products Group

15

NOTE: Ducts must have the same cross-sectional area as

the free area in the opening to which they are connected. The

minimum dimension of rectangular ducts shall be three

inches.

2.

One permanent opening, commencing within 12 inches

of the top of the enclosure shall be permitted where the

equipment has clearances of at least 1 inch from the

sides and back and 6 inches from the front of the appli-

ance. The opening shall communicate through a vertical

or horizontal duct to the outdoors, or spaces (crawl or

attic) that freely communicate with the outdoors and shall

have a minimum free area of:

a.

1 sq. in. per 3000 Btu per hr of the total input rating

of all equipment located in the enclosure.

b.

Not less than the sum of the areas of all vent con-

nectors in the confined space.

3.

Louvers, Grilles and Screens

a.

In calculating free area, consideration must be given

to the blocking effects of louvers, grilles and

screens.

b.

If the free area of a specific louver or grille is not

known, refer to Table 4, to estimate free area.

NOTE: If mechanically operated louvers are used, a means

to prevent main burner ignition and operation must be pro-

vided should louvers close during startup or operation.

Special Combustion and Ventilation Considerations

Operation of a mechanical exhaust, such as an exhaust fan,

kitchen ventilation system, clothes dryer or fireplace may cre-

ate conditions requiring special attention to avoid unsatisfac-

tory operation of gas appliances.

Specially Engineered Installations

The above requirements shall be permitted to be waived

where special engineering, approved by the authority having

jurisdiction, provides an adequate supply of air for combus-

tion, ventilation and dilution of flue gases.

Combustion Air Quality

The recommended source of combustion air is to use the out-

door air supply. Excessive exposure to contaminated com-

bustion air will result in safety and performance related

problems. However, the use of indoor air in most applications

is acceptable, except as follows:

1.

If the furnace is installed in a confined space it is recom-

mended that the necessary combustion air come from

the outdoors by way of attic, crawl space, air duct or

direct opening.

2.

If indoor combustion air is used, there must be no expo-

sure to the installations or substances listed in 3 below.

3.

The following types of installations may require OUT-

DOOR AIR for combustion, due to chemical exposure.

a.

Commercial buildings

b.

Buildings with indoor pools

c.

Furnaces installed in laundry rooms

d.

Furnaces installed in hobby or craft rooms

e.

Furnaces installed near chemical storage areas

f.

Permanent wave solutions

g.

Chlorinated waxes and cleaners

h.

Chlorine based swimming pool chemicals

i.

Water softening chemicals

j.

De-icing salts or chemicals

k.

Carbon tetrachloride

l.

Halogen type refrigerants

m. Cleaning solvents (such as perchloroethylene)

n.

Printing inks, paint removers, varnishes, etc.

o.

Hydrochloric acids

p.

Cements and glues

q.

Antistatic fabric softeners for clothes dryers

r.

Masonry acid washing chemicals

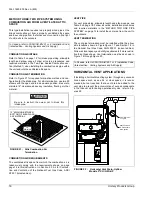

TABLE 4: ESTIMATED FREE AREA

Wood or Metal

Louvers or Grilles

Wood 20-25%

*

Metal 60-70%

*

*.

Do not use less than 1/4 in. mesh

Screens

†

†.

Free area or louvers an grilles varies widely; installer should

follow louver or grille manufacturer’s instructions.

1/4 in. mesh or larger 100%