Subject to change without notice. Printed in U.S.A.

035-17480-000 Rev. A (800)

Copyright

©

by Unitary Products Group 2000. All rights reserved.

Supersedes: 650.78-N1U (899)

Unitary

5005

Norman

Product

York

OK

Group

Drive

73069

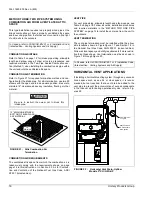

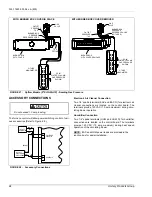

WIRING DIAGRAM - UPFLOW MODELS

NOTE: The furnace’s control system depends on correct polarity of the power supply.

T

O

D

W2

G

G

Y

W1

R

B

R

HEAT/COOL THERMOSTAT

ON

AUTO

Y

COOL

HEAT

OFF

W

LOW

HIGH

COOL

LOW HEAT

HI HEAT

USING A 2 STAGE THERMOSTATE.

7. REMOVE THE DELAY TIMER HARNESS WHEN

SEE NOTE 7

BLK

BLU

BLK

BLK

RED

RED

RED

---

120VAC

L C

A A

R V

T

U 0

E 2

N 1

BLU

RED

WHT

BLU

WHT

BLK

CONTROL BOARD

RELAY CONTACTS ON IGNITION

EAC

HUM

HUM

EAC

BLU

BLK*

BLU

BLK*

RED

BLK

2000

1600

080

1200

060

GRD

GRN

GRD

NO

C

2LP

NO

ROS1

NO

C

1LP

RED

ROS1

BLOWER SPEED CHART

CONNECTION DIAGRAM

6. MOTORS ARE INHERENTLY PROTECTED.

5. PROVIDE DISCONNECTS FOR ALL POWER SUPPLIES.

4. ALL REPLACEMENT COMPONENTS MUST BE PROPERLY GROUNDED.

3. CONNECTORS SUITABLE FOR COPPER CONDUCTORS ONLY.

HAVING A TEMPERATURE RATING OF AT LEAST 221

ß

F (105

ß

C).

MUST BE REPLACED, IT MUST BE REPLACED WITH WIRING MATERIAL

2. IF ANY OF THE ORIGINAL WIRE AS SUPPLIED WITH THE FURNACE

(C) LOCAL OR CITY CODES.

(B) CANADIAN ELEC. CODE (CEC) AND/OR

1. ALL FIELD WIRING PER: (A) NATIONAL ELEC. CODE (NEC) AND/OR

FIELD CONNECTION

EAC

HUM

HUM

HUM

EAC

EAC

EAC

HUMIDIFIER

BLOWER

MOTOR

1RC

90+ UP FLOW TWO STAGE FURNACE

RELAY

IGNITER

GV

GRD

DOOR SWITCH

N.O.SW

ELEMENTARY DIAGRAM

POWER SUPPLY 120-1-60

SEE NOTE 1

GRD

DS

C

NO

LS1

C

1LP

COM

120V

24V SEC

PRI

1T (40VA)

VENTOR

MOTOR

HSI

NOTES:

LEGEND

DOT DELAY ON TIMER

FUSE

ROS1 ROLL OUT SWITCH

LS1 PRIMARY LIMIT SWITCH

P6/S6 3 PIN PLUG & SOCKET AT GAS VALVE

P5/S5 3 PIN PLUG & SOCKET AT INDUCER MOTOR

P4/S4 2 PIN PLUG & SOCKET AT HOT SURFACE IGNITOR

P2/S2 5 PIN PLUG & SOCKET ON IGN. CONTROL BOARD

P1/S1 12 PIN PLUG & SOCKET ON IGN. CONTROL BOARD

HSI HOT SURFACE IGNITOR

GV GAS VALVE

DS DISCONNECT SWITCH

- CAUTION -

OPEN ALL DISCONNECTS BEFORE

SERVICING THIS UNIT

1T TRANSFORMER, 40VA

1RC RUN CAPACITOR

2LP PRESSURE SW, SECOND STAGE

1LP PRESSURE SW, FIRST STAGE

IDENTIFIED RUN CAPACITOR

24V CONNECTION ROOM THERMOSTAT

FACTORY WIRING AND DEVICES

----- FIELD WIRING AND DEVICES

JUMPERED.

AND COOL TERMINALS

* UNITS SHIPPED WITH HEAT

WHT

P1/S1

BLOWER SPEED

FOR DESIRED

SEE CHART

IGNITER

HOT SURFACE

WHT

WHT

BLK

WHT

BLK

1

2

3

1

P4/S4

P5/S5

BRN

GRN

GRD

FLAME

SENSOR

BLU

LS1

NEUT.

120VAC

120V

COM

24V SEC

PRI

N.O.SW

DOOR

C

NO

VENTOR

MOTOR

GRN

RED (LOW)

MOTOR

BLOWER

WHT (NEUT)

BLU (MED)

BRN

1RC

BRN

BLK (HI)

1

2

3

4

5

6

7

8

9

10

11

12

PRP

P2/S2

CIR

XFMR

LINE

4

3

2

1

WHT

WHT

BLU

BLK*

PARK

LOW

HEAT

HIGH

HEAT

COOL

1200

CFM

INPUT

035-17417-000A

5

BLK

2

BRN

RED

BRN

RED

WHT

BLK

RED

WHT

BLK

BLU

BRN

1ST STAGE

2ND STAGE

6

S

\

6

P

2 STAGE

VALVE

MAIN

M

C

HI

WHT

YEL

BLK

BLK

C

NO

2LP

ORN

COOL

PARK

HEAT LO

HEAT HI

LINE

XFMR

C

A

V

0

2

1

T

O

H

HUM

EAC

WY

R

G

B

1

W

2

TIMER

ON

DELAY

1

3

BLU

WHT

3A

120VAC

120

100

1400

2000

BLK

BLK*

BLK*

BLK

BLU

BLU

RED

RED

BLK

BLK