035-17480-000 Rev. A (800)

Unitary Products Group

25

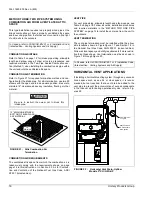

FURNACE ACCESSORIES

Electrical

2TH04701524

Thermostat, Two-stage Heat/Two-stage Cool, Deluxe 24V

2TB04700224

Thermostat Subbase

2TH04701024

Thermostat, Two-stage Heat/Two-stage Cool

2ET07700424

Programmable Thermostat, Two-stage Heat/Two-stage Cool

Non-Electrical

1NK0301

Condensate Neutralizer Kit

1NP0480

Propane Conversion Kit

1SR0302

External Side Filter Rack (6-Pack)

1BR0314

External Bottom Filter Rack - Cabinet “A”

1BR0317

External Bottom Filter Rack - Cabinet “B”

1BR0321

External Bottom Filter Rack - Cabinet “C”

1BR0324

External Bottom Filter Rack - Cabinet “D”

1CT0302

Concentric Vent 2” vent pipe

1CT0303

Concentric Vent 3” vent pipe

1PS0315

High Altitude Pressure Switch Kit (See form 035-14460-000 for proper application)

1PS0316

1PS0317

1PS0318

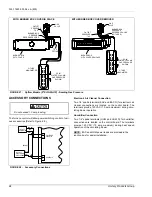

TABLE 7: AIRFLOW DATA - UPFLOW MODELS: P*XU/G9D-UP

MODELS: P1XU/

G9D-UP

SPEED

TAP

EXTERNAL STATIC PRESSURE, INCHES W.C.

0.10

0.20

0.30

0.40

0.50

0.60

0.70

0.80

0.90

1.00

60 / 55 / 1200 / "B"

80 / 75 / 1200 / "B”

HIGH

1465

1440

1390

1365

1315

1255

1190

1125

1055

940

MED

1085

1075

1060

1045

1030

1000

960

910

830

755

LOW

805

795

785

770

755

730

700

655

615

565

80 / 75 / 1600 / "C”

HIGH

1940

1905

1870

1815

1760

1700

1620

1555

1460

1305

MED

1400

1390

1380

1370

1355

1320

1285

1255

1210

1135

LOW

1245

1225

1205

1185

1165

1145

1125

1095

1050

970

100 / 95 / 1400 / "C”

HIGH

1785

1720

1650

1575

1495

1405

1315

1190

1050

880

MED

1430

1405

1375

1340

1290

1220

1130

1025

885

730

LOW

1150

1135

1120

1080

1045

1000

925

825

700

575

100 / 95 / 2000 / "C

HIGH

2355

2285

2205

2145

2080

1995

1905

1820

1715

1610

MED

1950

1915

1870

1830

1780

1710

1640

1560

1475

1375

LOW

1575

1555

1540

1505

1470

1430

1380

1315

1245

1150

120 / 112 / 2000 / "D”

HIGH

2375

2315

2245

2175

2100

2020

1935

1840

1755

1650

MED

1990

1955

1920

1875

1835

1775

1715

1630

1550

1450

LOW

1565

1550

1530

1505

1480

1445

1405

1350

1280

1200

NOTE: Data below reflects airflows with two return openings - two sides or one side and bottom.

100 / 95 / 2000 / "C”

HIGH

2365

2295

2215

2155

2090

2005

1915

1830

1725

1620

MED

1965

1930

1885

1845

1795

1725

1655

1575

1490

1390

LOW

1595

1575

1560

1525

1490

1450

1400

1335

1265

1170

120 / 112 / 2000 / "D”

HIGH

2385

2325

2255

2185

2110

2030

1945

1850

1765

1660

MED

2005

1970

1935

1890

1850

1790

1730

1645

1565

1465

LOW

1585

1570

1550

1525

1500

1465

1425

1370

1300

1220