035-17480-000 Rev. A (800)

16

Unitary Products Group

VENT PIPE SIZING (1-PIPE SYSTEM)

Refer to Table 5 to select the proper size piping for venting.

The size will be determined by a combination of furnace

model, total length of run, and the number of elbows required.

The following rules must also be observed.

NOTE:Furnace vent pipe connections are sized for 2-in. pipe.

Any pipe size change must be made outside the furnace cas-

ing in a vertical pipe section to allow proper drainage of vent

connections.

NOTE:An offset using two 45 degree elbows may be required

for plenum clearance when the vent is increased to 3".

1.

Long radius elbows are required for all units.

2.

Elbows are assumed to be 90 degrees. Two 45 degree

elbows count as one 90 degree elbow.

3.

One Vent terminal elbow is already accounted for and

should not be counted in the allowable total indicated in

the table. See “VENT TERMINAL LOCATION

CLEARANCES" Section on page 16 . This part is shown

shaded.

4.

All vent pipe and fittings must conform to American

National Standards Institute (ANSI) standards and Amer-

ican Society for Testing and Materials (ASTM) standards

D1785 (Schedule 40 PVC), D2665 (PVC-DWV), F891

(PVC-DWV Cellular Core), D2241 (SDR-21 and SDR-26

PVC), D2261 (ABS-DWV), or F628 (Schedule 40 ABS.

Pipe cement and primer must conform to ASTM Stan-

dards D2564 (PVC) or D2235 (ABS).

5.

The use of flexible connectors or no hub connectors in

the vent system is not allowed.

NOTE:If installing furnace at altitudes between 2000 - 4500

ft., intake and vent pipe length must be reduced by 10 ft. If the

installation requires the maximum allowable intake and vent

pipe length, the furnace must be converted for high altitude

operation. Refer to the proper high altitude application

instruction for details.

VENT TERMINATION (1-PIPE SYSTEM)

Side wall horizontal vent terminals and roof mounted vertical

terminals may be field fabricated. Standard PVC/SRD fittings

may be used. Terminal configuration must comply as detailed

in this section.

When selecting the locations for vent termination, the follow-

ing should be considered:

1.

Comply with all clearance requirements. Figure 17 on

page 16.

2.

Termination should be positioned where vent vapors will

not damage plants or shrubs or air conditioning equip-

ment.

3.

Termination should be located where it will not be

affected by wind gusts, light snow, airborne leaves or

allow recirculation of flue gases.

4.

Termination should be located where it will not be dam-

aged or exposed to flying stones, balls, etc.

5.

Termination should be positioned where vent vapors are

not objectionable.

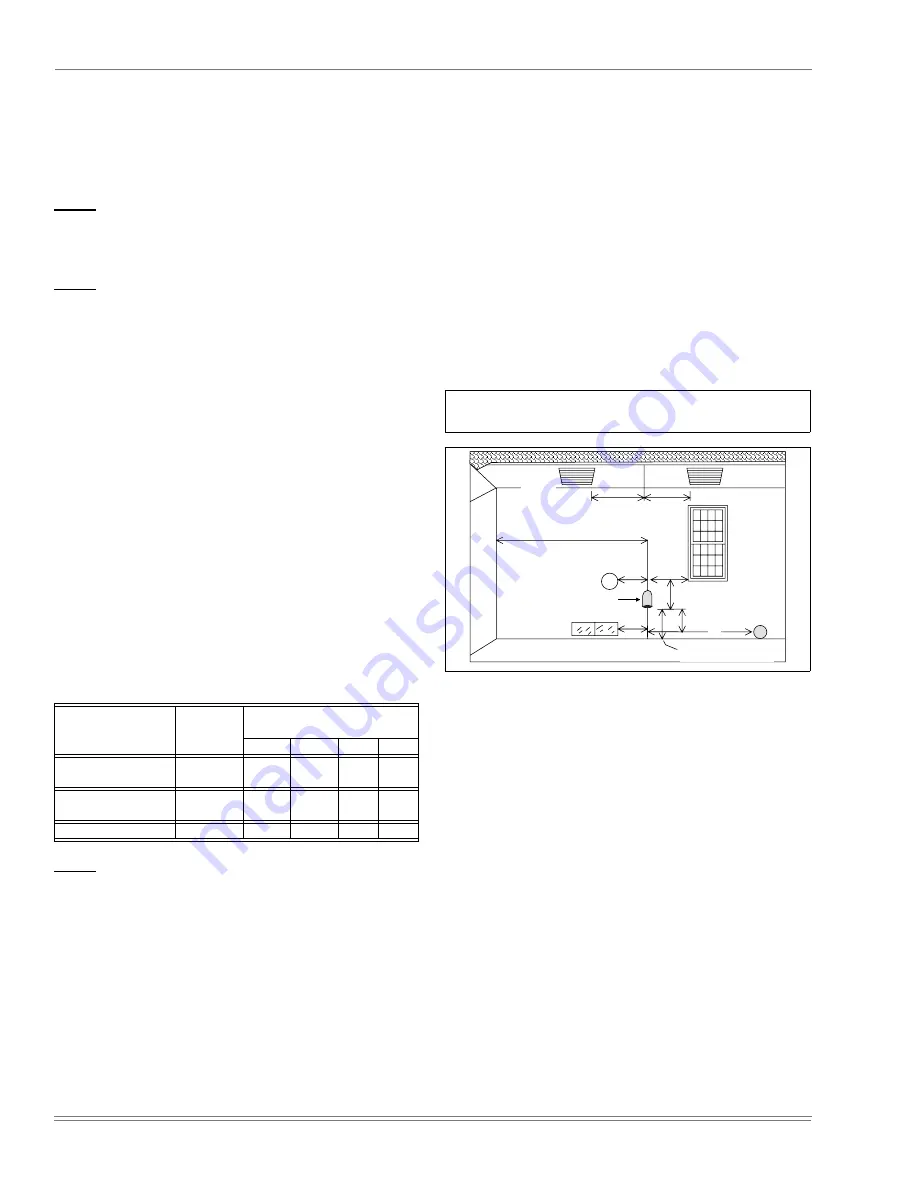

VENT TERMINAL LOCATION CLEARANCES

The vent must be installed with the following minimum clear-

ances (refer to Figure 17), and complying with local codes or

utility requirements or other authority having jurisdiction.

1.

1 foot above grade and above normal snow levels.

2.

Not above any walkway.

3.

4 feet below, 4 feet horizontally from, or 1 foot above any

door/window or gravity air inlet to the building, or from

gas or electric meters.

4.

6 feet from any inside corner formed by two exterior

walls. 10 feet is recommended where possible.

5.

At least 4 feet horizontally from any soffit or undereave

vent.

6.

10 feet from any forced air inlet to the building. Any fresh

air or make up inlet as for a dryer or furnace area is con-

sidered to be a forced air inlet.

TABLE 5: VENT PIPING / 1-PIPE SYSTEM

(ALL MODELS)

Model

Pipe Size

Max. Elbows vs. One Way Vent

Length (Ft.)

5-40

45

50

75

All Models Except:

120 / 112 / 2000 / D

2”

6

5

4

N/A

All Models Except:

120 / 112 / 2000 / D

3”

8

7

6

5

120 / 112 / 2000 / D

3” Only

6

5

4

N/A

In Canada, refer to CAN/CGA-B149.1 or.2 Installation Code

(latest edition - Venting Systems and Air Supply)

FIGURE 17 :

Minimum Vent Terminal

Clearances (1-Pipe System) - U.S. Only

INSIDE

CORNER

SOFFIT

VENTS

ELECTRIC

METER

4'

4'

4'

4'

6'

(10' RECOMMENDED)

4'

1' PLUS

SNOW CLEARANCE

4'

FORCED

AIR

INTAKE

10'

3'

FURNACE VENT