Installation

37

Greenstar 2000 – 6 721 820 552 (2021/02)

Side flue outlet [1].

▶ Mark from the centre line of the wall mounting template to the wall

which the flue will pass through.

▶ Allow for a rise of 52mm per metre length of flue, to give a 3° angle.

Example hole size.

• If a 60/100mm diameter flue is to be used, a 125mm diameter hole

is required.

• If using the weather sealing collar by pushing it through from inside

the property, then a 150mm diameter hole is required to

accommodate this.

Flue outlet position marked and ready to drill hole.

▶ Drill hole using a core drill or similar.

▶ Clear any debris from the site.

Appliance fixings and flue outlet drilled and ready.

▶ Remove the wall mounting template.

5.2

Appliance connections

WARNING

Appliance - gas connection

▶

Ensure the mains gas supply is isolated before starting any work

and follow all relevant safety precautions.

NOTICE

Appliance - hydraulic connections

▶ Ensure all water pipework, to be connected, are isolated/drained and

follow all relevant safety precautions.

▶ Be careful of plastic components when using a naked flame on

pipework.

Surplus water may be present inside the appliance due to factory testing.

External condensate pipework or internal pipe runs in unheated areas

such as lofts, basements and garages exposed to prolonged cold

temperatures should be protected (

chapter 4.5).

Connection sets fitting

Installing the connection sets

Connection set fitting

▶ For ease of installation the connection sets can be connected before

the appliance is mounted on the wall bracket.

Refer to figure 42.

▶ Ensure the sealing washers are fitted in the connection sets before

installing the connection sets.

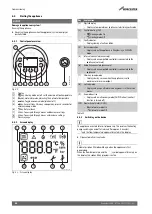

Fig. 42 Fitting the connection sets (for orientation reference)

Table 19

Description

#

From left case edge

#

From wall

CH flow

1

68mm

6

60mm

1)

1) 30mm with pipe tails

DHW outlet

2

133mm

7

30mm

Gas

3

200mm

7

30mm

DCW Inlet

4

267mm

7

30mm

CH return

5

332mm

6

60mm

7

6

0010033719-001

1

2

3

4

5