Benchmark Platinum-Edge: Operation-Service Manual

SECTION 4 – INITIAL START-UP

OMM-0137_D • GF-211

•

7/16/2019

Technical Support

•

(800) 526-0288

•

Mon-Fri, 8 am - 5 pm EST Page 38 of 146

NATURAL GAS Manual Combustion Calibration Instructions

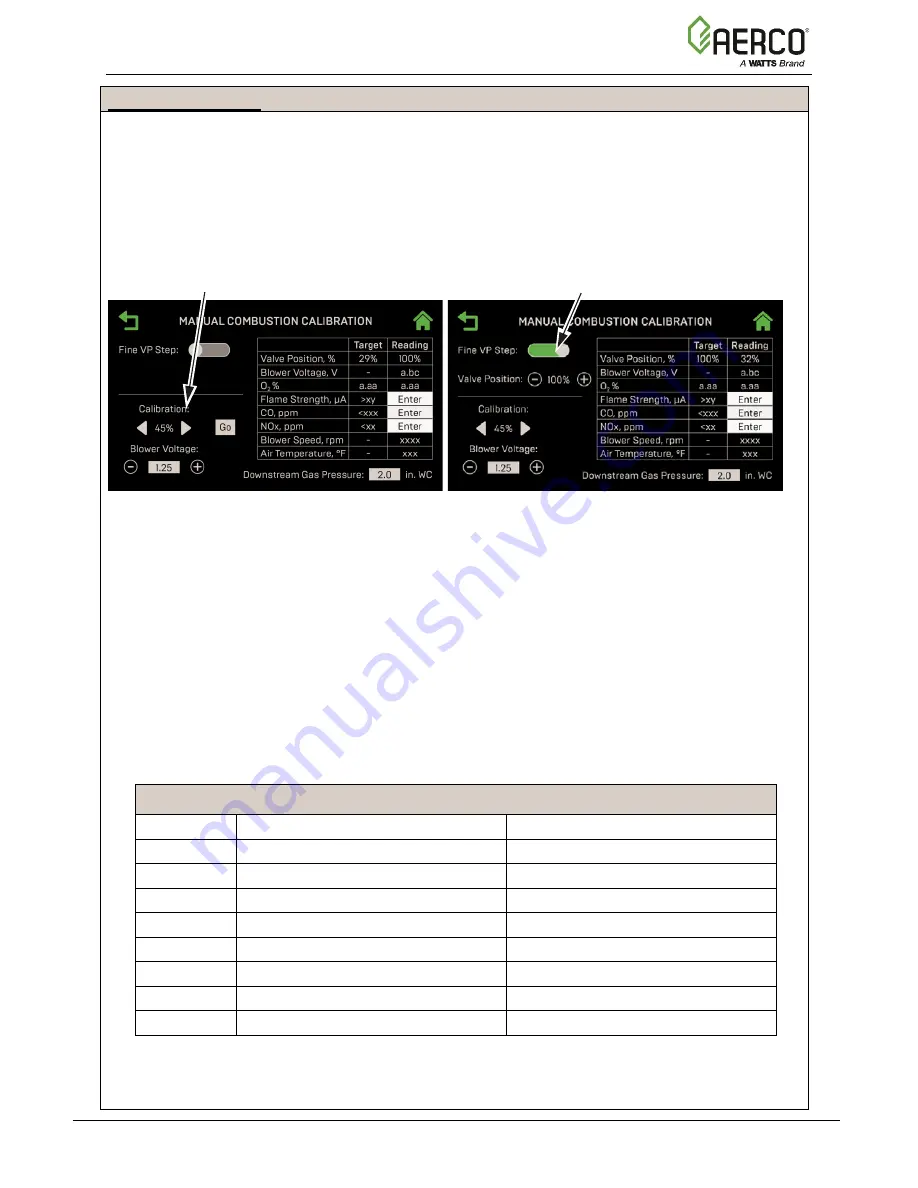

11. The main

Manual Combustion Calibration

screen appears. It provides two methods to

ramp the unit’s valve position up or down:

•

Method 1

: Toggle through the pre-set calibration points till you reach the desired

valve position, then press

Go

to go to that point (left image below).

•

Method 2

: Enable

Fine VP Step

, then manually press the

+

or

–

buttons once per

1% to bring the unit to the desired valve position (right image below).

PRESET CALIBRATION POINTS METHOD

FINE VP STEP METHOD

Figure 4-6: Manual Combustion Calibration Screens

12. Set the Controller’s Enable/Disable switch to

Enable

.

13. Change the valve position to 30%, press the

Go

button, then verify that the unit has ignited

and is operating as expected.

14. Use the

(Right) arrow key to change the valve position to

100%

, then press

Go

.

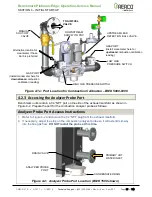

15. Verify that the gas pressure on the

downstream

side of the SSOV is within the required

range shown in Table 4-1. If it isn’t, remove the brass hex nut on the SSOV actuator to

access the gas pressure adjustment screw (Figure 4-3). Make adjustments using a flat-tip

screwdriver, slowly rotating the gas pressure adjustment (in 1/4-turn increments)

clockwise

to

increase

gas pressure or

counterclockwise

to

reduce

it. The resulting gas

pressure reading on the

downstream

manometer should fall in the range listed below.

TABLE 4-1: REFERENCE Gas Pressure Range @ 100% Fire Rate

Model

Single Fuel

Dual Fuel

BMK 750

2.0” ± 0.2” W.C. (0.50 ± 0.05 kPa)

-

BMK 1000

2.4” ± 0.4” W.C. (0.60 ± 0.10 kPa)

-

BMK 1500

3.6” ± 0.1” W.C. (0.90 ± 0.02 kPa)

3.6” ± 0.1” W.C. (0.90 ± 0.02 kPa)

BMK 2000

3.4” ± 0.2” W.C. (0.85 ± 0.05 kPa)

6.3” ± 0.1” W.C. (1.57 ± 0.02 kPa)

BMK 2500

2.0” ± 0.1” W.C. (0.50 ± 0.02 kPa)

5.8” ± 0.1” W.C. (1.44 ± 0.02 kPa)

BMK 3000

2.1” ± 0.2” W.C. (0.52 ± 0.05 kPa)

6.0” ± 0.2” W.C. (1.49 ± 0.05 kPa)

BMK 5000

6.3” ± 0.2” W.C. (1.56 ± 0.05 kPa) 6.3” ± 0.2” W.C. (1.56 ± 0.05 kPa)

BMK 6000

7.9” ± 0.2” W.C. (1.97 ± 0.05 kPa)

7.9” ± 0.2” W.C. (1.97 ± 0.05 kPa)

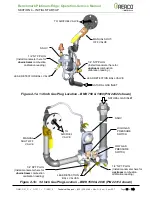

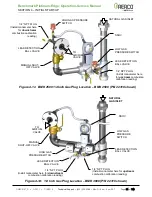

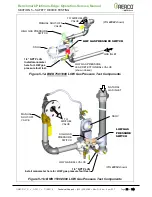

16. With the valve position still at 100%, insert the combustion analyzer probe into the exhaust

manifold probe opening (see Figure 4-2a – 4-2c in Section 4.2.3) and allow enough time

for the combustion analyzer reading to stabilize.

PRE-SET CALIBRATION CONTROLS

FINE VALVE POSITION CONTROLS