3

Introduction

The Model 960 control provides sophisticated,

demand-based water conditioning by incorporating a

microprocessor and a water meter to electronically

monitor the amount of water used daily. This fully

programmable control allows you to fine tune the

conditioner’s operation to meet your customer’s

application. The Series 255 valve combines design

simplicity with reinforced Noryl* construction to provide

an uncommonly reliable appliance. The inherent

reliability of the system means a long life of efficient,

trouble-free water conditioning. If maintenance

becomes necessary, the Series 255/960 water

conditioning system offers a unique separation

capability illustrated in this manual.

*Noryl is a trademark of General Electric Company

Special Features

•

Memory Retention.

During a power outage,

critical operating information in the control’s

memory is stored in a special electronic device.

This information includes the time of day, water

usage amounts, daily average water usage, all

programming data and the number of days since

the last regeneration. When power is restored, the

information is returned to the microprocessor and

operation resumes as if an outage never occurred.

The time of day will be late by the length of the

power outage. If an outage of one or more hours

occurs, the time of day should be reset but no other

reprogramming is necessary. The optional

non-rechargeable battery backup feature will allow

the control to keep track of time and any water

usage for up to two days during a power outage.

•

Fully programmable regeneration cycle times.

The control is factory programmed with typical

regeneration cycle times for easy installation. The

control allows the Backwash, Rinse, and Purge

cycle times to be set by the installer to fine tune the

conditioner’s operation.

•

Automatic double regenerations for exhausted

resin beds.

If the water usage exceeds 150% of

the system capacity between regenerations, the

control will automatically call for a second

regeneration the next day even if no water is used.

This feature is included to make sure that an

exhausted resin bed is completely recharged.

•

Selectable reserve options.

The control can be

programmed to operate with one of four different

reserve options (see Parameter P15, Table 3). The

options include starting a regeneration only at a

specific time of day or having an immediate

regeneration when the capacity is exhausted. The

control can also have a fixed reserve which is a

percentage of the total system capacity or a

variable reserve which adjusts the reserve

depending upon the water usage patterns of your

customer.

•

Separate Time of Day and Time of Regeneration

settings.

The control defaults to a 2:00 a.m.

regeneration time for easy installation, but the

installer may set the regeneration to occur at any

time of the day.

•

WQA S-101 features.

The control can be

programmed to freeze the values for Salt Amount

and Capacity so the customer can’t alter them after

installation (see Parameter P18, Table 3).

•

Selectable 12-or 24-hour clock.

(See Parameter

P13, Table 3.)

•

Selectable U.S. or metric units of measure.

Use

grains per gallon of hardness, pounds of salt, and

kilograins of capacity for U.S. units. Use milligrams

per liter of hardness, kilograms of salt and

kilograms of capacity for metric units (see

Parameter P12, Table 3).

•

Selectable calendar override.

One to 30 days are

available to automatically regenerate the

conditioner if the water usage hasn’t caused a

regeneration. The default value is zero which

disables this feature (see Parameter P14, Table 3).

•

Design reliability.

Solid-state electronics assure

many years of trouble-free performance. The

metering system has only one moving part, the

rotating turbine that measures water usage and

generates electrical pulses that are counted by the

microprocessor to determine the need to

regenerate.

•

Guest cycle.

An extra regeneration can be

achieved at any time by pressing the REGEN

button on the Model 960 front panel. It takes just a

few minutes for the regeneration to start. The

regeneration takes about two hours. This feature is

beneficial when the customer expects to use more

than the normal amount of water; for example,

guest visits or an extra heavy laundry day.

•

Manual double regeneration.

Back-to-back

regenerations can be run by pressing the REGEN

push button after the first regeneration has been

running for at least one minute. This can be used to

recharge the resin bed that has operated without

salt for an extended period of time.

Superior Design

•

Fewer parts than any control system of

comparable function and most controls of lesser

function.

•

The valve may be indexed manually with or without

power to any one of its service or regeneration

positions. The Regeneration Cycle Indicator on the

Содержание Series 255

Страница 18: ...18 Pressure Graphs Tested with 3 4 inch Brass Manifold Bar Bar Bar...

Страница 20: ...20...

Страница 21: ......

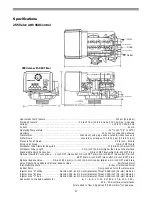

Страница 23: ...23 Meter Adapter Bypass Valve Piping Boss and Wall Mount Transformer Inlet Outlet Drain...