12

Brine Draw Value

Parameter P7 is used by the control to calculate the

brine draw time. The default value of 25 was selected

for a “B” injector with low water pressure or an “A”

injector with moderate water pressure. If this does not

match your installation, press the SET button and enter

a new value. Refer to Table 4 for the correct value. Find

the injector used in the 255 valve. The injector cap is

labeled with the injector letter and the injector is color

coded for easy identification. Next, determine the

typical water pressure for this installation. The Brine

Draw Value is an estimate of the flow rate of brine

through the injector. This rate varies with water

pressure and injector type as shown in Table 4. The

control calculates the brine draw time using this value

and the salt amount. The brine draw time is added to

the Rinse Time (P10) to determine the total Brine

Draw/Slow Rinse Time.

•

This control does not use Parameter P8. No entry

is needed for this parameter.

•

Parameter P12 selects the units of measure. Be

sure that this is set to the correct value before

entering any data for Parameters P3, P4 or P5.

•

Parameter P13 selects the clock display mode. If

the 12-hour mode is selected, a PM indicator is

used. If the 24-hour mode is selected, the PM

indicator is not used.

•

Parameter P15 has four allowable values. Values 0

or 1 will cause the control to wait for Parameter P2,

time of day of regeneration, to begin the

regeneration. Values 2 or 3 will cause the control to

start the regeneration as soon as the capacity is

exhausted.

•

When Parameter P15 selects a variable reserve

type, 0 or 2, Parameter P16 is used to calculate the

initial seven average daily water usage values. The

control multiplies the total capacity by the

percentage entered for Parameter P16 and uses

that value as the initial average daily usage for each

day of the week until water usage establishes new

averages.

•

Parameter 17 has two allowable values, 0 or 1,

however, the 1 is reserved for future options and

thus should not be used. Improper regenerations

will occur if P17 is set to 1.

•

Parameter P18 allows the installer to lock the Salt

Amount and Capacity values so they cannot be

changed. When Parameter 18 is set to 1, those two

settings can only be viewed when the control is in

the Level II mode. The settings will be skipped

when the control is in the Level I mode. When

Parameter 18 is set to zero, the Salt Amount and

Capacity can be viewed and changed in either

Level I or Level II.

•

Parameter P19 is used at the factory to enter

default values. This parameter does not need to

be

changed. Using this parameter will erase the

values for all other parameters and replace them

with default values. Improper regenerations will

occur if P19 is set to a 1 or 3.

Regeneration

When the control begins a regeneration, the display will

alternate between Time of Day and Regen Time

Remaining. The Regen Time Remaining is shown in

minutes. The control will start and stop an internal

motor which drives the camshaft through the various

regeneration positions. The control uses the

information entered in the parameters shown in Table 3

to determine how long each part of the cycle should

last. The control will stop the camshaft at the correct

location for each part of the regeneration cycle.

If power fails during a regeneration cycle, the cycle

completes normally when the power is restored.

Note:

The REGEN button is only active when the

display is alternating between Time of Day and

Capacity. When programming Level I or II parameters,

the REGEN button is not active.

Conditioned water is available when the control enters

the brine refill cycle. The Regen Time Remaining in

regeneration will continue to count down until the

indicator points to REGENERATION COMPLETE.

Manual Regeneration

To force the control to perform a regeneration, press the

REGEN

button. This button is located on the front of

the control. When you press the REGEN button, the

control performs a full regeneration of the conditioner.

If you press this button again more than one minute

after regeneration begins, but before the

regeneration is complete, a second regeneration

will start when the first regeneration is finished.

The

display will freeze and only show the Regen Time

Remaining as an indication that the second

regeneration will be performed. When the first

regeneration is complete, the second one will begin

and the display will alternate between Time of Day and

Regen Time Remaining.

Table 4 - Brine Draw Value

Injector

Color

Brine

Draw

Value at

30 psi

Brine

Draw

Value at

50 psi

Brine

Draw

Value at

70 psi

A

White

19

26

31

B

Blue

24

30

37

C

Red

29

37

40

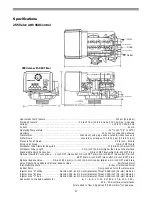

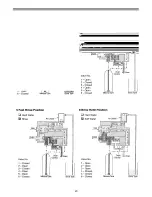

Содержание Series 255

Страница 18: ...18 Pressure Graphs Tested with 3 4 inch Brass Manifold Bar Bar Bar...

Страница 20: ...20...

Страница 21: ......

Страница 23: ...23 Meter Adapter Bypass Valve Piping Boss and Wall Mount Transformer Inlet Outlet Drain...