27

Problem

Possible Cause

Solution

10. Continuous

regeneration.

Camshaft does not

stop at the end of

regeneration.

a. Broken projection on drive gear.

b. Defective switch.

a. Replace control.

b. Replace control.

11. Control does not

regenerate

automatically or when

REGEN button is

depressed.

a. Transformer unplugged.

b. No electric power at outlet.

c. Defective motor.

d. Broken gear.

e. Binding in gear train.

f.

Defective switch.

a. Connect power.

b. Repair outlet or use working outlet.

c. Replace control.

d. Replace control.

e. Replace control.

f.

Replace control.

12. Control does not

regenerate

automatically but does

regenerate when

REGEN button is

depressed.

a. If water flow display is not operative,

refer to item 5 in this table.

b. Incorrect hardness and capacity

settings.

c. Defective circuit board.

a. Refer to item 5 in this table.

b. Set new control values. Refer to the

Programming section.

c. Replace control.

13. Run out of soft water

between

regenerations.

a. Improper regeneration.

b. Fouled resin bed.

c. Incorrect salt setting.

d. Incorrect hardness or capacity

settings.

e. Water hardness has increased.

f.

Restricted meter turbine rotation

due to foreign material in meter

housing !

g. Excessive water usage below

1/5 gallon per minute.

a. Repeat regeneration making certain

that correct salt dosage is used.

b. Use resin cleaner.

c. Set salt control to proper level. Refer to

the Programming section in this

manual.

d. Set to correct values. Refer to the

Programming section of this manual.

e. Set to correct value. Refer to the

Programming section in this manual.

f.

Remove meter housing, free up

turbine, and flush with clean water.

Turbine should spin freely; if not,

replace meter.

g. Repair leaky plumbing and/or fixtures.

14. Control does not draw

brine.

a. Low water pressure.

b. Restricted drain line.

c. Injector or injector screen plugged !

d. Injector defective !

e. Valve disc 2 and/or 3 not closed.

f.

Air check valve prematurely closed.

a. Increase water pressure.

b. Remove restriction.

c. Clean injector and screen. Refer to the

Cleaning the Injector/Injector Screen

section in this manual.

d. Replace injector and cap.

e. Manually operate valve stem to flush

out foreign matter holding disc open.

Replace if needed.

f.

Briefly put control into brine refill

status. Refer to the Manual

Regeneration section in this manual.

Replace or repair air check valve if

needed.

Table 6 - Troubleshooting Procedures

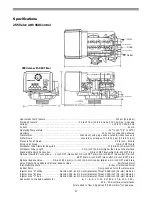

Содержание Series 255

Страница 18: ...18 Pressure Graphs Tested with 3 4 inch Brass Manifold Bar Bar Bar...

Страница 20: ...20...

Страница 21: ......

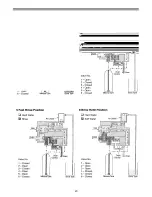

Страница 23: ...23 Meter Adapter Bypass Valve Piping Boss and Wall Mount Transformer Inlet Outlet Drain...