15

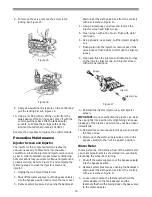

8. To remove the valve, remove the screw in the

locking bar, Figure 15.

Figure 15

Figure 16

9. Apply downward hand pressure on the control and

pull the locking bar out, Figure 16.

10. Using a rocking motion, lift the control from the

tank adapter. If the O-ring seals come off with the

control, put them back into the tank adapter

sockets. Lubricate the O-rings with silicone

lubricant (Autotrol part number 1013501.)

Reverse the procedure to replace the control module.

Preventive Maintenance

Injector Screen and Injector

The injector is the component which creates the

vacuum necessary to draw brine into the water

conditioner. Clean the injector and injector screen once

a year in order to maintain proper water conditioning.

Some locations may require more frequent injector and

screen servicing. Refer to Figure 17 and complete the

following steps to clean the injector screen and

injector:

1. Unplug the wall-mount transformer.

2. Shut off the water supply or put the bypass valve(s)

into the bypass position and remove the rear cover.

3. Relieve system pressure by opening the backwash

drain valve (the sixth valve back from the control)

with a screwdriver, Figure 11.

4. Using a screwdriver, unscrew and remove the

injector screen and injector cap.

5. Clean screen with a fine brush. Flush with water

until clean.

6. Using a needle-nose pliers, pull the injector straight

out.

7. Flush water into the injector screen recess of the

valve body to flush debris out through the injector

recess.

8. Clean and flush the injector. Lubricate the O-rings

on the injector, injector cap, and injector screen

with silicone lubricant.

Figure 17

9. Reinstall the injector, injector cap, and injector

screen.

IMPORTANT:

Do not overtighten the plastic cap. Seat

the cap lightly into position. Overtightening can cause

breakage of the plastic cap which may not be evident

immediately.

10. Reinstall cover, reconnect electric power, and reset

the time of day.

11. Slowly open the water supply valve or return the

bypass valve(s) to the “not in bypass” position.

Water Meter

In rare instances, the turbine wheel of the water meter

can collect small particles of oxidized iron, eventually

preventing the wheel from turning.

1. Shut off the water supply or put the bypass valve(s)

into the bypass position.

2. Relieve system pressure by opening the backwash

drain valve (the sixth valve back from the control)

with a screwdriver, Figure 11.

3. Loosen and remove the fasteners that hold the

meter adapter to the tank adapter and the

fasteners that hold the piping boss or bypass valve

to the meter adapter.

Injector

Injector Cap

Screen

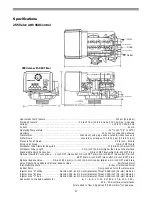

Содержание Series 255

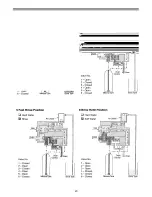

Страница 18: ...18 Pressure Graphs Tested with 3 4 inch Brass Manifold Bar Bar Bar...

Страница 20: ...20...

Страница 21: ......

Страница 23: ...23 Meter Adapter Bypass Valve Piping Boss and Wall Mount Transformer Inlet Outlet Drain...