26

Table 6 - Troubleshooting Procedures

Problem

Possible Cause

Solution

1. Capacity display stays

at 9999 even though

there is water usage.

a. Total system capacity was

calculated to be a value greater than

9999.

a. As the water usage continues, the

remaining capacity will drop below

9999 and then other values will be

shown.

2. Timer beeps when left

arrow button is

pressed.

a. Button is only active in the

programming mode.

a. Refer to the Programming the Control

section.

3. Timer does not

respond to REGEN

button.

a. Button is not active in the

programming mode.

a. Refer to the Regeneration section.

4. Timer does not display

time of day.

a. Transformer unplugged.

b. No electric power at outlet.

c. Defective transformer.

d. Defective circuit board.

a. Connect power.

b. Repair outlet or use working outlet.

c. Replace transformer.

d. Replace control.

5. Timer does not display

correct time of day.

a. Outlet operated by a switch.

b. Power outages.

a. Use outlet not controlled by switch.

b. Reset Time of Day.

6. No water flow display

when water is flowing

(colon does not blink).

a. Bypass valve in bypass position.

b. Meter probe disconnected or not

fully connected to meter housing.

c. Restricted meter turbine rotation

due to foreign material in meter !

d. Defective meter probe.

e. Defective circuit board.

a. Shift bypass valve into service

position.

b. Fully insert probe into meter housing.

c. Remove meter housing, free up turbine

and flush with clean water. Turbine

should spin freely. If not, refer to the

Water Meter Maintenance section.

d. Replace control.

e. Replace control.

7. Control display is

frozen at Regen Time

Remaining.

a. Back to back regenerations were

requested.

a. Refer to the Manual Regeneration

section.

8. Control regenerates at

the wrong time of day.

a. Power outages.

b. Time of day set incorrectly.

c. Time of regeneration set incorrectly.

a. Reset time of day to correct time of

day.

b. Reset time of day to correct time of

day.

c. Reset time of regeneration.

9. Timer stalled in

regeneration cycle.

a. Motor not operating.

b. Motor runs backwards.

c. No electric power at outlet.

d. Incorrect voltage or frequency (Hz).

e. Broken gear.

f.

Defective switch.

g. Air leak in brine connections

(pressure locked flapper).

h. Binding of camshaft.

i.

Water pressure greater than

125 psi during regeneration.

j.

Defective circuit board.

a. Replace control.

b. Replace control.

c. Repair outlet or use working outlet.

d. Replace timer and/or transformer with

one of correct voltage and frequency

(Hz).

e. Replace control.

f.

Replace control.

g. Check all junction points and make

appropriate corrections.

h. Remove foreign object obstruction

from valve discs or camshaft.

i.

Install pressure regulator to reduce

pressure.

j.

Replace control.

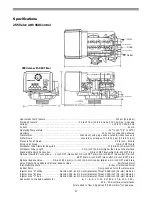

Содержание Series 255

Страница 18: ...18 Pressure Graphs Tested with 3 4 inch Brass Manifold Bar Bar Bar...

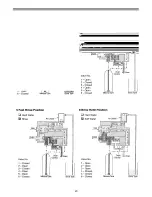

Страница 20: ...20...

Страница 21: ......

Страница 23: ...23 Meter Adapter Bypass Valve Piping Boss and Wall Mount Transformer Inlet Outlet Drain...