37

VERSION 01/2018

ORDER NUMBER DOC 2385674

TOPFINISH Bell 1S

4. Connect the air hoses for bearing air (BA), bearing air monitoring (BAM), drive air (DA)

and stop air (STA).

Ensure that the assignment of the drive air (DA) and the stop air (STA) is correct,

thereby the direction of rotation of the high-speed rotary atomizer is not influenced

negatively.

A wrong direction of rotation causes damage to the high-speed rotary atomizer.

5. Mount and connect the air hoses for steering air (SA1/SA2).

6. Connect air hoses for main needle valve (CA), product release (M), dump (DM) and

bell flushing (FB).

7. If necessary, fix product tube in order to fit the nozzle.

The nozzle can be fitted with ease once the air bearing has been removed.

8. Fit product nozzle in accordance with the planned application rate.

Different product nozzles with different application rates are available.

9. Connect the high-voltage cable.

10. Connect the product hoses for the dump return line (DM).

11. Connect the product hoses for the product supply line (M).

12. Connect the product hoses for the flushing agent supply line (FB).

13. Connect the air hoses for controlling to all the valves.

Laying hoses

The hose lengths of the various hoses must be selected to ensure a sufficient reserve

in all the reciprocator's working positions.

14. Slide supplied sleeve onto the optical fiber and fasten it (see Chapters

15. Fit optical fiber for recording speed and lock accordingly with locking pin.

Assembling optical fiber

The optical fiber is very prone to kinks and/or bending radii. These may cause damage

to it. Assemble the optical fiber with great care.

16. Secure cable for optical fiber and high-voltage cable with cable ties.

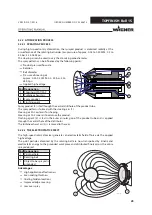

17. Mount the air deflector ring in accordance with the selected bell diameter.

18. Mount the bell with mounted distributor to the drive shaft by locking the drive

spindles.

They are locked by pressing and holding down the locking button (see picture below).

B_06681

19. Slide union nut air ring up to stop and lock it with the bayonet fitting.

There may be no gap at the rear of the union nut!