7

2.

Delivery and installation

The lathes are carefully packed in our factory.

Please check the following on delivery:

1. whether the packaging has been damaged and/or:

2.

whether the lathe shows signs of damage in transit or if there is any other reason for

complaint. In this case we request your immediate notification. Claims made at a later

date cannot be accepted.

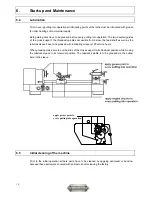

The lathe must be installed on appropriate, plain and firm ground.

This would be, for example:

a base cabinet such as to be found in our accessories programme

a work bench strong enough to carry the weight of the machine without warping with an even

surface (see technical data and check with spirit level).

a steel plate

The lathe must be screwed to the base. Use the 9 mm holes in the machine base.

Good results

and a minimum of vibration during operation can only be guaranteed if the above mentioned

requirements for secure mounting are observed.

The machine should be installed in a well lighted area and electrical cables with earthed sockets

and O-conductors must be installed close to the machine so that the mains cable is not subject to

any tension whatsoever. The mains cable should be such that, for example, by means of a multiple

socket, a coolant unit can also be connected.

3.

Conditions for best results

i

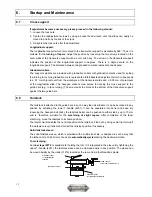

Fix the machine to a sturdy, level support.

Use sharp processing tools.

Adjust speed setting and feed to fit the material and diameter of the tool.

The clamping position of the tools is to be as close as possible to the workpiece.

Clamp the workpieces tightly and without vibrations.

Long pieces are to be supported by the tailstock or a stay.

Apply coolant and lubricant for better surface quality (finish) and dimensional

accuracy.

The clamping surfaces for clamping tools and workpieces must be clean.

Grease the machine sufficiently.

Use the correct machining tools for removing the material from the workpieces.

Set the correct bearing clearances and align guides.

Содержание D2400

Страница 5: ...5 1 Machine dimensions 1 1 D2000 1 2 D2400...

Страница 6: ...6 1 Machine dimensions 1 3 D3000...

Страница 28: ...28 13 Drawings and list of parts 13 3 Lead screw drive for D2400 and D3000...

Страница 32: ...32 13 Drawings and list of parts 13 5 Drive with gear transmission for D2000...

Страница 34: ...34 13 Drawings and list of parts 13 6 Cross support...