12

6.

Startup and Maintenance

6.7 Cross

support

If adjustment becomes necessary, please proceed in the following manner:

1. Loosen the lock nuts.

2. Tighten the readjustment screws by using a socket head wrench until the slides can easily be

moved to and fro by means of the crank.

3. Re-tighten the lock nuts after the adjustment.

Longitudinal support:

The longitudinal support which is mounted to the transversal support is pivotable by 360°. Thus, it is

suitable for the

turning of tapers

. Adjust the position by loosening the two screws located on the

outer sides of the transverse support with a 4 mm allen key. The arrow on the transversal support

indicates the position of the longitudinal support in degrees. There is a degree scale on the

longitudinal support. The distance between two graduation marks represents one degree.

Graduated collars:

The support spindles are provided with graduation collars with graduation marks used for setting

the turning tools. One graduation mark represents a

0.05 mm

feed adjustment which corresponds

to a 0.1 mm chip removal from the workpiece at the transversal slide and a 0.05 mm chip removal

at the longitudinal slide. The hexagon socket screw serves for locking the cross support to the

guide bars (e.g. in face turning.) The screw pulls the block at the bottom of the transverse support

against the two guide bars.

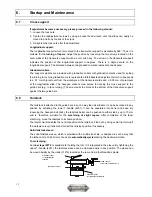

6.8 Tailstock

The tailstock is attached to the guide bars in such a way that it is slidable. It can be be locked in any

position by actuating the lower T-handle (4251). It can be separated into barrel and base. By

loosening the hexagon bolt (424), the tailstock barrel can be pushed to either side by up to 10 mm

and is, therefore, suitable for the

machining of slight tapers

. After completion of the taper

machining, move the tailstock to its home position.

The lateral mark indicates the central position of the tailstock. Find out by doing some trial turning if

the workpiece is cylindrical and correct the tailstock position if necessary.

Solid tailstock sleeve:

The solid tailstock sleeve, which is provided with a millimetre scale, is designed in such a way that

the lathe centre, drill barrel or chuck are

automatically ejected

during the backward motion.

Tool clamping:

An

inner taper MT 2

is available for holding the tool. It is integrated in the sleeve. By tightening the

upper T-handle (4251), the tailstock sleeve can be clamped easily in any position. The sleeve can

be moved axially by the crank (31212) located at the rear end via the threaded spindle.

spanner bolt (424)

T-handle (4251)

T-handle (4251)

crank (31212)

to move the tailstock sleeve

for tightening the tailstock

for tightening the

tailstock

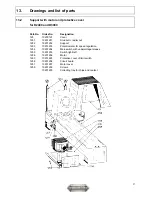

Содержание D2400

Страница 5: ...5 1 Machine dimensions 1 1 D2000 1 2 D2400...

Страница 6: ...6 1 Machine dimensions 1 3 D3000...

Страница 28: ...28 13 Drawings and list of parts 13 3 Lead screw drive for D2400 and D3000...

Страница 32: ...32 13 Drawings and list of parts 13 5 Drive with gear transmission for D2000...

Страница 34: ...34 13 Drawings and list of parts 13 6 Cross support...