21

8

.

Applications

8.2.4

Altering the feeds or thread pitch

for

D3000

1.

Working with the automatic longitudinal feed

a.

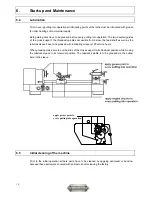

Turn the gear lever (19) to the symbol longitudinal turning. Slightly turn the lead screw by

means of the ball ended crank (31212) until the clutch disc engages.

b.

Switch-on the direction switch on the right of the substructure.

middle position

=

off

left pressed

=

feed to the spindle

right pressed

=

feed to the tailstock

Adjust the feed speed with the potentiometer.

c.

After completion of the automatic longitudinal turning, turn the direction switch to the middle

position again.

2.

Working with the thread cutting unit

a

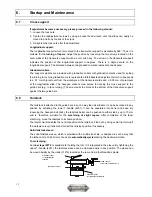

At first the change gears needed for the desired thread pitch have to be mounted. The

machine is delivered with the wheels Z 36 and Z 24 for a thread pitch of 1.5 mm put on. When

cutting metric threads toothed wheel Z 48 remains on the change gear quadrant as indicated

in table 6.22. When cutting inch threads this wheel has to be replaced by toothed wheel Z 34.

For the different thread pitches only the tooth wheels B (beside Z 48) and C (on the main

spindle) are to be changed according to table 6.22.

b.

Pre-select slowest spindle speed.

c.

Turn the gear lever (19) to the symbol thread cutting. The lever must remain in this position

until the entire thread has been cut. For repeating the cutting process the machine must be

stopped by turning the reversing switch at the end of the cutting process and the thread cutting

tool is being removed from the cutting area. Now turn the reversing switch to left turning and

the support moves towards the tailstock. When the thread cutting tool is located approx. 5 mm

away from the thread start, stop the machine and move the transversal support to the starting

position of the first cut adding the desired chip removal. Then turn the reversing switch to right

turning and start the thread cutting process. The gear lever (19) remains in this position until

the thread cutting process has been completed.

RUECKW

VORW

0

AUS

NOT

direction switch

potentiometer

handle (19)

handle (31212)

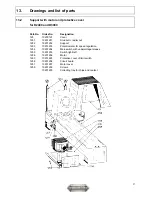

Содержание D2400

Страница 5: ...5 1 Machine dimensions 1 1 D2000 1 2 D2400...

Страница 6: ...6 1 Machine dimensions 1 3 D3000...

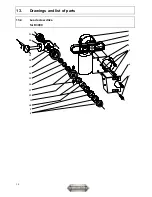

Страница 28: ...28 13 Drawings and list of parts 13 3 Lead screw drive for D2400 and D3000...

Страница 32: ...32 13 Drawings and list of parts 13 5 Drive with gear transmission for D2000...

Страница 34: ...34 13 Drawings and list of parts 13 6 Cross support...