22

4.3.7. Terminals for EPO.

The UPS has two terminals to install an external button of

emergency output shutdown (EPO).

4.3.8. Control panel.

This UPS

has a sophisticated control panel based on a DSP (Digital

Signal Processor) that performs as interface between the UPS and

end-user.

Each UPS is equipped with an alphanumerical LCD panel, which

automatically informs the end-user of the current status of the

equipment and electrical measurements. It is based on a tree

diagram, allowing an easy bro

wsing through its screens.

4.3.9. Control software and communications.

AFC Control (Adaptive Feedforward Cancellation).

It consists in the use of digital resonators connected in parallel and

set to those frequencies where the consigns or perturbations to

refuse are expected.

This control technique allows doing the follow of the sinewave

signals of reference of the output voltage in the inverter and input

current of the active rectifier.

It is important to high

light that the different controls of the UPS

do not operate either independently or locally, but they interact

between them in such a way that it is an overall controller of

coupled type. It means operating advantages like

to adapt the

rectifier to the load conditions immediately.

The digital control software works at two different levels:

4.3.9.1. Control software at low level.

•

Input

three-phase rectifier controller

: PFC control and

battery charge loops. The structure adopted of independent

control per phase of cascade type allows managing both single

phase and three phase inputs.

The AFC control technique has also been applied, to assure a

sinewave mains currents, with a THDi < 2%, and in phase

shifting with the voltages, to balance the active power of all

the system, to accelerate its response and make it insensitive

to the load transients.

In normal conditions, the rectifier is running and charging the

batteries, controlling the charging current and floating voltage

at any moment according to the temperature of themselves.

The system is also in charge of minimizing the charging current

ripple that flows through them.

When the input voltage or frequency is out of the correct

operating range, it is shut down and batteries are responsible

for keeping the inverter in operation. Meanwhile, they supply

the loads connected at the output of the equipment till the

battery voltage decreases at the end of back-up time.

Another important feature of the rectifier is its bidirectional

capacity in operation. This allows consigning a battery

discharging current even with existing mains. This quality

performance will make it possible to do a battery test both in

full load and in no load c

onditions.

•

Out

put three- phase rectifier controller:

being independent

per phase, it is easily adapted to different settings, either single

phase or three phase.

It highlighted the use of the AFC control technique that allows

getting an output voltage with a THDv lower than 1,5% in non-

linear load at the output and good dynamic response against

unexpected step

loads.

•

Switching algorithm of the bypass thyristors

.

•

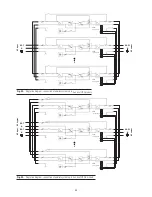

Parallel control

: high speed communication and inverter

parallel connection.

4.3.9.2. Managing software of the equipment.

Managing and control of different parts.

Visualization software for user interface.

Software of communication and protocol implementation.

Managing software of parallel system.

4.3.9.3. Communications.

•

C

OM port to relays

: It supplies a digital signals in a dry

contact way, which makes the dialogue between the

equipment and other machines or devices possible.

By default the equipment is supplied with 4 signal relays with

a preset programming (see chart 2), which can be modified at

factory or by the

S.T.S.

upon request. Chart 6 shows all the

alarms that can be set to any relay. A fifth relay can be supplied

as an option and upon request, which can be defined in the

purchase order.

Also there is a “shutdown” input that allows shutdown the

inverter.

The

most common use of this type of port is to supply the

necessary information to the closing file software.

•

COM port RS-232 and RS-485

: By means of the same DB9

connector supplies the RS-232 and RS-485 communication

ports. They are mutually exclusive between them and they are

used to connect the UPS with any machine or device that has

this standard bus.

The

RS-232

port consists in the serial transmission of data, in

such a way that it can send a lot of information through a

communication cable of 3 wires.

The

RS-485

, unlike other serial communication channels, it

uses 2 wires only to dialogue among the systems connected to

this network. The communication is established by sending and

receiving signals in differential mode, so it gives the system

high immunity against the noise

and long range (approx. 800m).

The used protocol is “MASTER/SLAVE” type. The computer or

IT system (“MASTER”) asks for a determined data, and the UPS

answers immediately (“SLAVE”).

4.4. OPERATING PRINCIPLE OF AN EQUIPMENT.

This UPS

series is a double conversion system AC/DC, DC/AC with

sinewave output that supplies a safe protection in extreme

conditions of electrical power supply (fluctuations of voltage,

frequency, electrical noises, blackouts and mains faults,