25

4.5. OPERATING STRUCTURE OF A PARALLEL SYSTEM.

This

Uninterruptible Power Supply Systems series is designed

and thought as «parallel» connection with a maximum of four units,

in the condition that they are the same model (setting, voltage,

power, frequency, back-up time, ...), all of them without adding

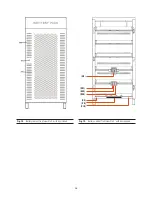

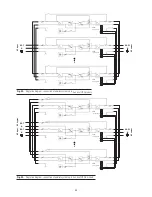

hardware. Fig. 22 and 23, as examples, show the circuit diagrams

of a three-phase input/three-phase output parallel system, with and

without separate static bypass line. Both circuit diagrams are only

showing the input-output power connections and the parallel

control BUS.

A part from the possible setting, conceptually, the parallel systems

are divided into two similar structures and at the same time very

different depending on the application.

Systems connected in parallel or active parallel, supply the loads

equally among them. Less when there is only one UPS, the system

will be able to be redundant or non-redundant depending on the

needs and requirements of the application.

•

Simple parallel system (non-redundant)

: a non-redundant

parallel system, is that one where all UPSs supply the required

power by the loads. Total power of the system based on N

equipment of nominal power rate Pn, is N x Pn.

If the system is operating with a load close or equal to the

maximum and one of the faults, the load will be shifted to

bypass automatically with “ make before break technique”,

because it will not be able to support the consumption demand

due to the overload that it will be caused in the rest of UPSs.

•

Redundant system

: a redundant system is that one has one

or more UPSs than the minimum required by the total power of

the system (depending on the redundancy level), being the load

fair shared among them. So, the fault of any of them will cause

the damage that UPS will be out of the system and the rest

will continue supplying the load with all the guarantees. Once

the damaged UPS is fixed, it can be connected to the system in

order to recover the redundant condition.

A system with his configuration increases the reliability and

assures a quality of AC power supply for the most critical loads.

The quantity of redundant equipment to be connected has to

be studied according to the requirements of the application. No

matter Parallel connection is redundant or not, it adds several

advantages apart from the connection itself:

•

Higher punctual power and back-up time

: in a parallel

system of N+M equipment, it is considered the nominal

maximum load of N equipment and +M are the reserve on

es,

so:

N, is the quantit

y of equipment in parallel, corresponding to

the minimum quantity required by the total needed power.

+M, is the additional quantity of equipment corresponding

to the residual safety power (redundant equipment).

Although, in practice it can drain the total power in which the

N+M system can supply, the redundancy r

equirement or

conception does not advice it and in compensation there is a

surplus of dynamic power against load demands. i.e., a

redundant parallel system with 3 UPS of 40 kVA and N+1

configuration, the nominal maximum load contemplates 80 kVA

(2x40 kVA), although the system can accept load demands up

to 120 kVA (3x40 kVA).

Ther

efore, the fact of M reserve equipment, increases

the back-up time of the set because the battery set is higher.

•

Modularity

: capacity can be added to a UPS parallel system

by adding equipment of the same feature, without needing to

replace the equipment already installed. i.e., if time later, an

installation with a parallel system of 2 UPSs is detected that the

capacity of this system is not enough, it can be opted for adding

a third equipment to the system, without replacing the 2

original equipment.

The UPS parallel system management of

UPS

series is done by a

MASTER-SLAVES protocol, where only one equipment (MASTER)

takes the control of the rest ones (SLAVES). So, the control of the

output voltage, bypass shifting, disconnections, mains

synchronization are managed by the MASTER equipment, and

transmitted to the SLAVES equipment through the management

bus of the parallel system.

This MASTER or SLAVE condition is dynamic as it is described later

and it will depend on several factors (initial status of the

equipment, chronological order of commissioning or shutdown of

the system through one equipment or other)