25

SECTION 7

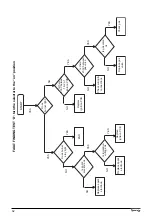

CHECKS, ADJUSTMENTS AND FAULT FINDING

7.1

CHECKING APPLIANCE OPERATION

When carrying out any repairs or servicing to the

appliance, the relevant commissioning procedure

must be undertaken to ensure the continued safe

operation of the appliance. Particular attention

should be made to ensure gas soundness, water

soundness, and the electrical integrity of the

appliance.

7.2

APPLIANCE MODE OF OPERATION

NOTE: there must be sufficient system water

pressure (min. 0.5 bar) to ensure the water

pressure switch is activated. If there is insufficient

system pressure the pump and fan will be

prevented from operating.

7.2.1

SELECTOR SWITCH IN THE OFF POSITION

When the selector switch is in the OFF position,

there is no LED display or LED status indicator.

The appliance will not respond to any heating/

HW requests.

Active Functions:

●

frost-protection system

●

pump anti-block.

7.2.2

SELECTOR SWITCH IN THE ON POSITION

When the selector switch is in the ON position,

the status LED is illuminated and the LED display

shows the current temperature measured at the

thermistor.

Active Functions:

●

frost-protection system

●

pump anti-block

●

fan anti-block.

7.2.3

APPLIANCE FUNCTIONS

●

Frost-protection: this function is only active

when there are no requests for heating or HW.

Should the temperature of the primar y

thermistor drop below 7

°

C, the pump will be

activated for approximately 20-minutes. Should

the temperature of the primary thermistor

exceed 10

°

C during this period, the cycle will

be aborted. If the temperature drops below

4

°

C, the boiler will operate on minimum power

until the temperature of the primary thermistor

reaches 30

°

C. Thereafter the pump & fan will

over-run for 30-seconds.

●

Anti-block cycle: when there has been no

heating or HW request for 19-hours, the anti-

block cycle is activated. The pump will be

activated for a period of 1-minute if the selector

switch is in the ON position, the fan will also

be active for 1-minute.

7.2.4

HEATING/HW MODE

With the selector switch in the ON position and

any additional controls (time clock, room

thermostat, etc,) calling for heat, the appliance

will operate in the heating/HW mode. The pump

and fan will be active. The operation of the fan

causes the analogue pressure switch (PAD) to

deliver a signal voltage to the control PCB. If the

signal voltage is sufficient a slow ignition

sequence is enabled, whereby the current

supplied to the gas valve modulating coil is

progressively increased from minimum to

maximum over a period of 8-seconds. During this

period the ignition electrode sparks continuously

even if the burner has ignited.

NOTE

If the spark/sensing electrode does not sense

ignition the appliance will then go to lockout.

Ignition is sensed by the electronic circuitry to

ensure flame stability at the burner. Once

successful ignition has been achieved, the

electronic circuitry allows 75% of the full gas rate

through the appliance. After 15 minutes the gas

rate is increased to maximum (100%).

When the set-point has been reached (the

position of the temperature selector) as measured

at the primary thermistor, the appliance will begin

the modulation phase whereby the fan and gas

valve will continuously modulate to maintain the

set-point. If the temperature continues to rise and

exceeds the set-point by 6

°

C, the burner will shut

down and the boiler will perform a three-minute

anti-cycle (timer delay).

A new ignition sequence will be enabled when

the 3-minute anti-cycle has been performed and

the temperature at the primary thermistor has

dropped 6

°

C below the set-point.

NOTE

The timer delay can be de-activated by the

insertion of a ‘jumper’ on the PCB or by isolating

the appliance from the electrical supply for 30

seconds.

When the request for heating/HW has been

satisfied, the appliance pump and fan may

continue to circulate to dissipate any residual heat

within the appliance.

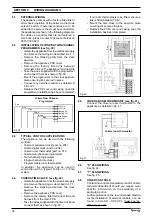

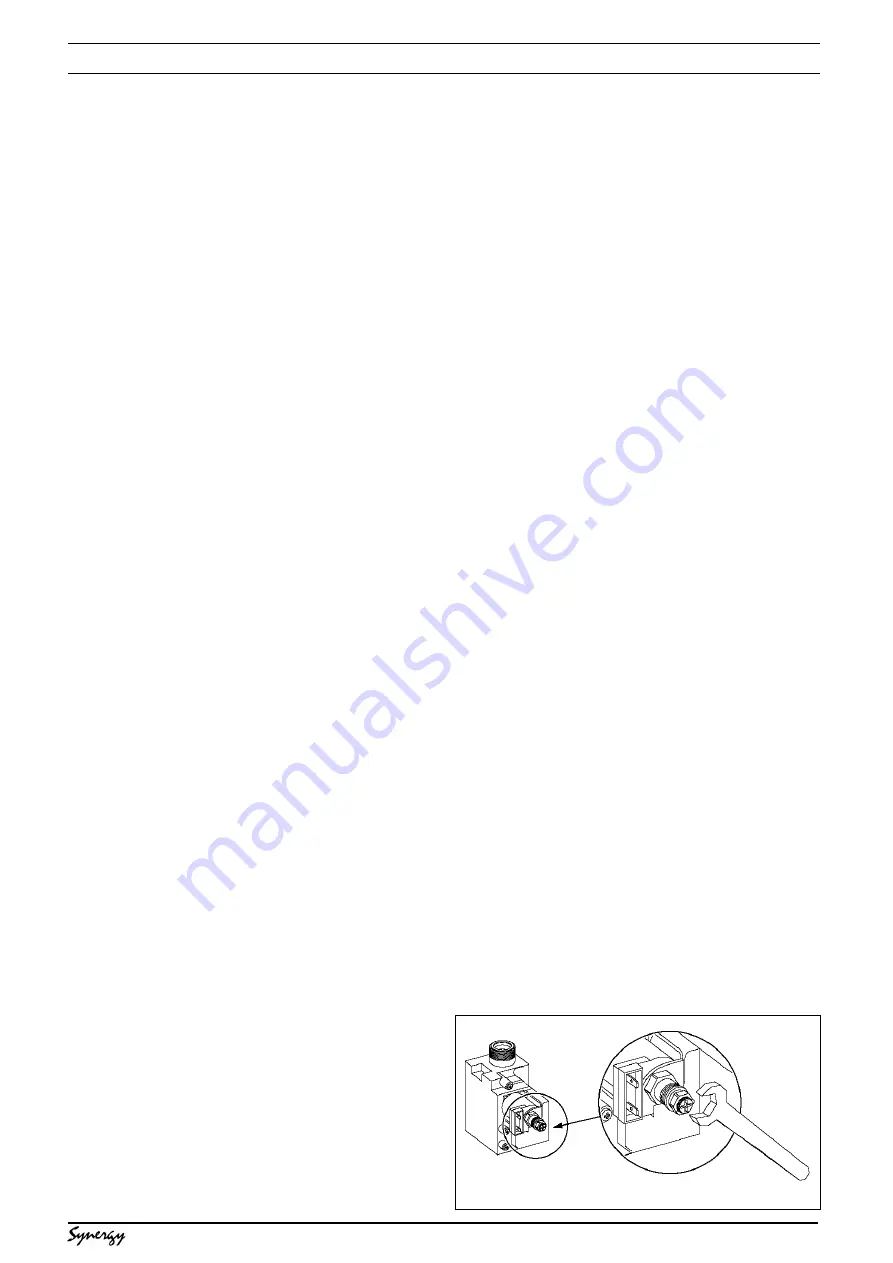

7.3

CHECKING AND ADJUSTING BURNER PRES-

SURE (see fig. 17)

Although the burner pressure is factory set, it is

necessary to check it during servicing or if the

gas valve has been removed.

Isolate the appliance from the electrical supply

and attach a suitable manometer to the gas valve

outlet test nipple.

7.3.1

SETTING THE MAXIMUM BURNER PRES-

SURE (see fig. 36)

Light the boiler as described in 5.6 and compare

the reading on the manometer with the value

described in 2.3. If adjustment is required, remove

the protective cap from the gas valve modulating

coil assembly and turn the outer (10mm) nut

clockwise to increase, or counter-clockwise to

decrease the burner pressure.

Fig. 36

Содержание Synergy 29

Страница 1: ...Installation Servicing Instructions THESE INSTRUCTIONS TO BE RETAINED BY USER ...

Страница 40: ...38 Fig 45 ...