BULLETIN 10-11 /

Page 5

Factors which affect valve performance and may make it necessary

to adjust the valve are:

1.

Low temperature difference (TDs) between the refrigerant and

the air

2.

TEV bulb location

3.

Balance between compressor and evaporator

4.

Ratio of load to TEV capacity

5.

Condenser capacity

6.

Operation of several fixtures on multiple installation

7.

Seasonal variation in head pressure caused by extreme changes in

ambient air temperature.

Note:

Valve Types F, (E)BF/SBF, Q, A, M, V, K, and W have non-

rising adjusting stems and a change in adjustment does not change

the stem position.

When setting valves on multi-evaporator refrigeration systems with

pressure or temperature sensitive evaporator control valves, the

following procedure is recommended:

1.

Evaporator Pressure Regulating Valve (ORI Type): the ORI valve

is set first at the minimum load condition. Then, if necessary, the

expansion valve is adjusted to the desired superheat setting while

under the normal operating load condition.

2.

Temperature Sensitive Evaporator Regulating Valves (CDS

Type): The CDS valve is forced into a fully open position first.

Then the expansion valve is adjusted to the desired superheat

setting at full load condition. Finally, the controller for the CDS

is set to the desired temperature. Contact Sporlan Valve

Company, or the case manufacturer, for additional details on

setting the CDS controller.

When the adjustment is completed on the TEV, always tighten the

adjusting stem packing nut and replace the seal cap tightly.

Many expansion valves are made

non-adjustable

for use on

Original Equipment Manufacturer’s units, particularly those valves

used on residential air conditioning and heat pump systems. These

valves are set at a superheat predetermined by the manufacturer’s

laboratory tests and cannot be adjusted in the field.

Some

non-adjustable

models are modifications of standard

adjustable type valves. This is done by using a solid bottom cap

instead of one equipped with an adjusting stem and seal cap. These

valves can be identified by an

N

preceding the standard valve designa-

tion. Adjustable bottom cap assemblies are available for converting

most non-adjustable valves to the adjustable type. However, this is

rarely required. If symptoms indicate that a valve adjustment is

needed, carefully check the other possible causes of incorrect

superheat, pages 6 through 10, before attempting an adjustment.

How to Determine Superheat

Correctly

1.

Measure the temperature of the suction line at the bulb location.

2.

Obtain the suction pressure that exists in the suction line at the

bulb location by

either

of the following methods:

a.

If the valve is externally equalized, a gauge in the external

equalizer line will indicate the desired pressure directly and

accurately.

b.

Read the gauge pressure at the suction valve of the

compressor. To the pressure add the estimated pressure drop

through the suction line between bulb location and

compressor suction valve. The sum of the gauge reading and

the estimated pressure drop will equal the approximate

suction line pressure at the bulb.

3.

Convert the pressure obtained in

2a

or

2b

above to saturated

evaporator temperature by using a temperature-pressure chart.

4.

Subtract the two temperatures obtained in

1

and

3

– the differ-

ence is superheat.

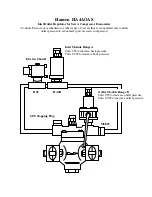

Figure 8 illustrates a typical example of superheat measurement on

an air conditioning system using Refrigerant 22. The temperature of

the suction line at the bulb location is read at 52°F. The suction

pressure at the compressor is 66 psig and the estimated suction line

pressure drop is 2 psi …66 psig + 2 psig = 68 psig at the bulb, which

is equivalent to a 40°F saturation temperature. (Use dew point

temperature for refrigerant blends.) 40°F subtracted from 52°F =

12°F superheat.

Note:

Refrigerated case manufacturers frequently use a “tempera-

ture difference” method to approximate superheat. This procedure

consists of measuring the temperature of a location on the evaporator

which is representative of saturated vapor temperature; and, then

subtracting that temperature from the outlet evaporator temperature

which is measured at the bulb location.

While this method of reading “superheat” is acceptable on those

manufacturer’s cases where the pressure drop through the evaporator

is low, Sporlan does not recommend the “temperature difference”

method for other types of systems.

How to Change the Superheat

Setting

Note: There are some valve bodies (G, EG, C, S, EBS

and EMC) that have a packing nut around the adjust-

ment stem. It may be necessary to loosen the packing

nut slightly to turn the adjusting stem. Do not forget

to retighten the nut after the superheat is set.

To reduce the superheat, turn the adjusting stem

counter-

clockwise

. To increase the superheat, turn the adjusting stem

clockwise

. When adjusting the valve, make no more than one turn

of the stem at a time and observe the change in superheat closely to

prevent

over-shooting

the desired setting. As much as 30 minutes

may be required for the new balance to take place after an adjust-

ment is made.

What's Your

Superheat?

OBTAIN SUCTION PRESSURE

68 PSIG (at bulb)

Temperature

here reads

52

°

40

°

12

°

SUPERHEAT

Figure 8

Содержание VSM 71-701

Страница 1: ...1 VPN 35391S February 2006 Rev 05 Price 60 00...

Страница 2: ...2...

Страница 20: ...20...

Страница 52: ...53 Pre Start Up Check List...

Страница 99: ...99 Recommended Spare Parts List...

Страница 104: ...104 Gate Rotor...

Страница 110: ...110 Main Rotor VSS...

Страница 112: ...112 Main Rotor VSR...

Страница 114: ...114 Slide Valve Cross Shafts and End Plate...

Страница 118: ...118 Capacity Slide Volume Slide Carriage Assembly Slide Valve Carriage Assembly...

Страница 134: ...134 Miscellaneous Frame Components VSS Screw Compressor VSR Mini Screw Compressor...

Страница 138: ...138 C FlangeAdapter Components 630 620 610 640 601 641 630 601 620 610 640 641 642 650 651...

Страница 140: ...140 Replacement Parts Tools...

Страница 144: ...144 GaterotorAssembly...

Страница 148: ...148 Main Rotor Slide Valve Cross Shafts and End Plate Models 71 401 Only Counter clockwise...

Страница 151: ...151 See Next Page for Models 501 701 Main Rotor Slide Valve Cross Shafts and End Plate V S M Parts List...

Страница 152: ...152 Main Rotor Slide Valve Cross Shafts and End Plate Model 501 701 Only Clockwise...

Страница 154: ...154 Volume Ratio Capacity Slide Carriage Assembly Slide Valve Carriage Assembly...

Страница 158: ...158 Miscellaneous Frame Components Model VSM 501 701 Model VSM 71 401...

Страница 160: ...160 Replacement Parts Accessories Housing Accessories C Flange Assembly...

Страница 166: ...166 Haight Pumps...

Страница 170: ...3 Refrigerating Specialties Division...

Страница 184: ...C A R T R I D G E H E A T E R S Hi Temp Cartridge heaters are designed for optimum performance above and beyond the norm...

Страница 236: ......

Страница 237: ......

Страница 238: ......

Страница 243: ......

Страница 244: ...168...