E

N

G

L

IS

H

30

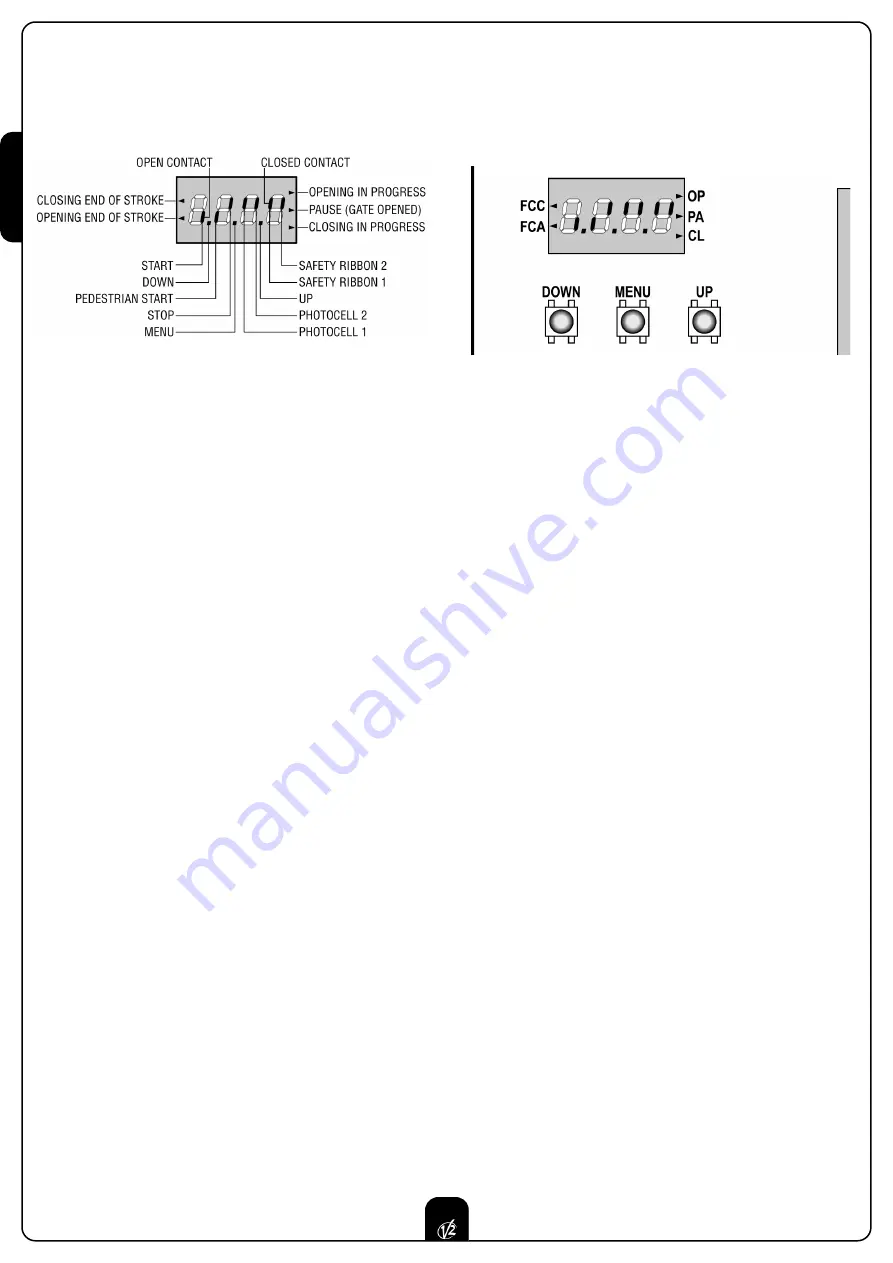

CONTROL PANEL

When power is on, the control unit checks that display correctly

operates by switching on all segments for 1.5 sec.

8.8.8.8.

Firmware version, e.g.

Pr 2.0

, will be viewed in the following 1.5

sec. Panel will be viewed upon completion of this test.

The control panel represents the physical status of the

terminal board contacts and of the program mode keys: if the

upper vertical segment is on, the contact is closed; if the lower

vertical segment is on, the contact is open (the above picture

shows an instance where the inputs START, START P, FOTO 1,

FOTO 2,COSTA 1, COSTA 2 and STOP have all been correctly

connected).

Points being among display digits show the status of

programming push-buttons: as soon as a push-button is pressed,

its relevant point turns on.

The arrows on the display left side show the status of the ends of

stroke. As for a one door-gate, arrows turn on when its end of

stroke shows that the gate is completely closed or

completely open.

As for a two-door gate, arrows turn on when both the ends of

stroke show that both the doors are completely closed or

completely open; the arrow will blink in case only one door

reaches its end of stroke.

WARNING:

these functions have not been activated in case of

ends of stroke being connected in series to the motor.

The arrows on the display right side show the gate status:

• The highest arrow turns on when the gate is into its opening

phase. If it blinks, it means that the opening has been

caused by a safety device (border or obstacle detector).

• The central arrow shows that the gate is on pause. If it

blinks, it means that the time countdown for the automatic

closing has been activated.

• The lowest arrow blinks when the gate is into its closing

phase. If it blinks, it means that the closing has been

caused by a safety device (border or obstacle detector).

USE OF DOWN MENU AND UP KEYS FOR

PROGRAMMING

Control unit time and function programming is made within a

special configuration menu, to which you can access and where

you can shift through

DOWN, MENU

and

UP

keys placed under

the display.

Hold down the MENU key until

dEF

appears on display, to

activate the programming mode while display views the panel.

Configuration menu consists of a list of configurable items; the

wording appearing on display will show the current selected item.

By pressing DOWN, you will pass to the next item; by pressing UP,

you will return to the previous item.

By pressing MENU, you can view the current value of selected

item and possibly change it.

The last menu item (

FinE

) allows storing the carried out

changes and going back to the control unit normal operation.

You must exit from programming mode through this menu item

if you do not want to lose your configuration.

WARNING:

in case no operation is carried out for more than one

minute, the control unit exits from the programming mode

without saving any of your setups and changes, which will get

lost.

By holding down the DOWN key, configuration menu items will

scroll fast, until item

FinE

is viewed. Viceversa, by holding down

the UP key, items will scroll fast backwards until item

dEF

is

viewed. In this way, you can quickly reach either the top or

bottom of the list.

There are the following three kinds of menu items:

• Function menu

• Time menu

• Value menu

Function menu setup

Function menus allow selecting a function from among a group

of available options. When you enter into a function menu, the

current active option will be viewed; you can scroll all available

options through DOWN and UP keys. By pressing the MENU key,

you will activate the option viewed and you will return to the

configuration menu.