E

N

G

L

IS

H

28

SAFETY RIBBONS

The control unit considers two kinds of safety ribbons,

depending on the terminal to which they are connected:

•

Type 1 (fixed):

they are mounted on walls or on other fixed

obstacles that are approached by the gate doors during the

opening phase. When type 1 safety ribbons operate during

the gate opening phase, the control unit will close the doors

for 3 seconds, then it stands still; when type 1 safety

ribbons operate during the gate closing phase, the control

unit will stand still immediately. The direction of the gate at

next command of START or PEDESTRIAN START depends

upon the parameter STOP (it inverts or continues the

motion). If the input STOP is disabled, the command makes

the motion continue in the same direction.

•

Type 2 (mobile):

they are mounted to the door ends.

When type 2 safety ribbons operate during the gate opening

phase, the control unit will stand still immediately; when

type 2 safety ribbons operate during the gate closing, the

control unit will open the doors for 3 seconds, then it will

stand still. The direction of the gate at next command of

START or PEDESTRIAN START depends upon the parameter

STOP (it inverts or continues the motion). If the input STOP

is disabled, the command makes the motion continue in the

same direction.

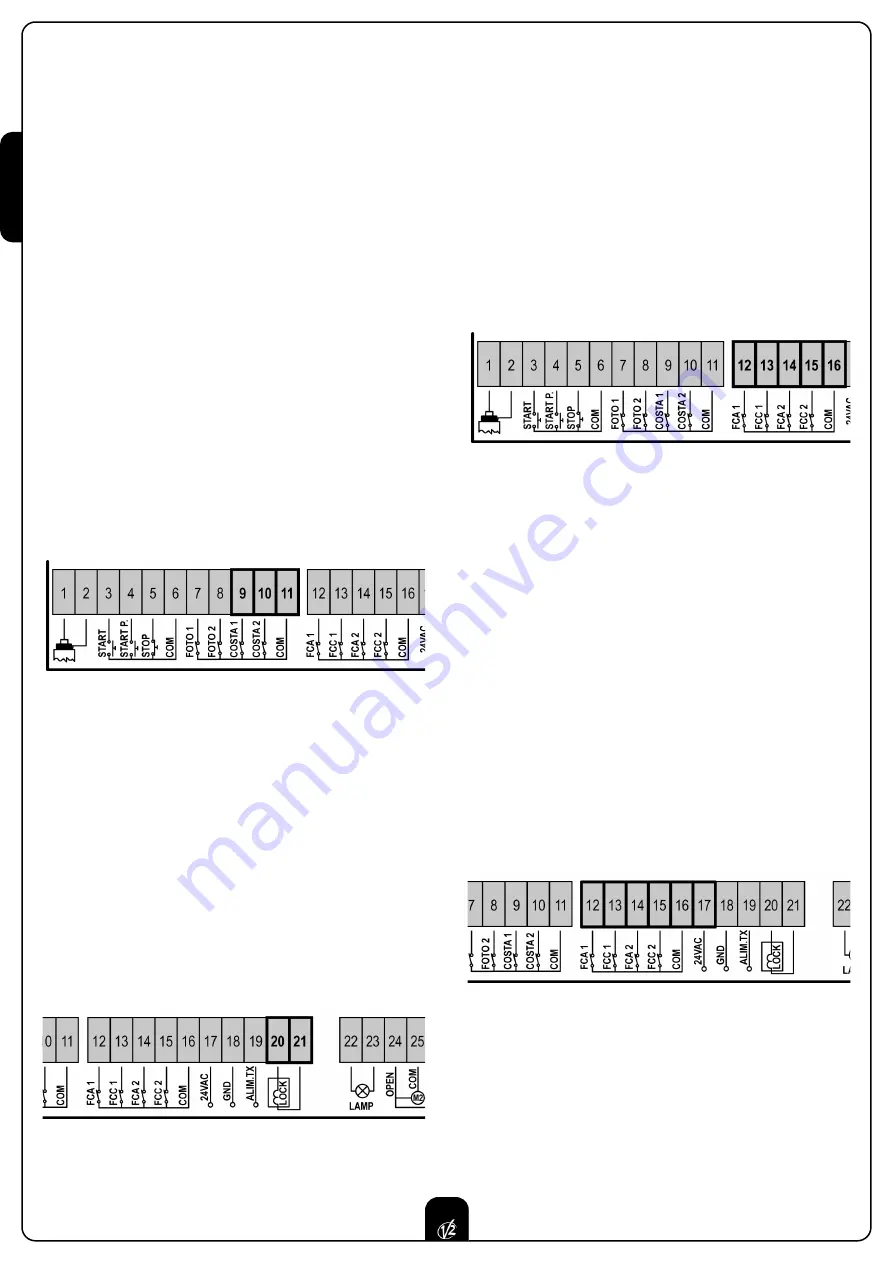

Connect type 1 safety ribbons cables between terminals

9

and

11

of the control unit.

Connect type 2 safety ribbons cables between terminals

10

and

11

of the control unit.

In order to meet the requirements of the EN12978 rules, it is

necessary to install safety edges controlled by a control unit

continuously checking the proper working. If using control units

suited to the test by power outage, connect the power supply

cables of the control unit between terminals 19 and 18 of the

CITY1. Otherwise, connect them between terminals 17 and 18.

WARNING:

• Make use of safety ribbons having outputs with normally

close contact.

• Outputs of same kind safety ribbons must be connected in

series.

LOCK

An electric lock can be assembled on the gate, to ensure a good

closing of doors. Make use of a 12V lock.

Connect lock cables to terminals

20

and

21

of the control unit.

END OF STROKE

CITY1

control unit supports the two following kinds of end of

stroke:

• end of stroke in series of motor winding.

• end of stroke equipped with a normally close switch that will

be opened as soon as the door reaches its position desired.

The control unit automatically recognizes ends of stroke in-series

of the motor windings so no connection or programming is

required.

Ends of strokes equipped with a normally close switch must be

connected to the control unit terminal board as follows:

• opening end of stroke in door 1 between terminal

12

and

16

.

• closing end of stroke in door 1 between terminal

13

and

16

.

• opening end of stroke in door 2 between terminal

14

and

16

.

• closing end of stroke in door 2 between terminal

15

and

16

.

ENCODER (only for CITY1-ECD)

With CITY1-ECD, you can use encoder-equipped motors to

control the exact position of the gates. Furthermore, the encoders

allow you to detect if the gate panels jam in an improper position

due to obstacles.

For encoder operation, when in the closed position, both gate

panels must rest against a mechanical stop. Each time the

controller is turned on the gate is closed until the gate panels

touch the mechanical stop in order to realign the encoders.

The limit switch input terminals are used for the encoder

connection. For this reason limit switches and encoders cannot be

connected at the same time.

Connect the encoder signal cables for Motor 1 on terminals

14

and

15

.

Connect the encoder signal cables for Motor 2 on terminals

12

and

13

.

Connect the negative power supply pole for both encoders to

terminal

16

.

Connect the positive power supply pole for both encoders to

terminal

17

.

STOP

For a better safety, you can fit a stop switch that will cause the

immediate gate stop when activated. This switch must have a

normally close contact that will get open in case of operation.

In case the stop switch is operated while the gate is open, the

automatic closing function will always be disabled. To close the

gate again, you will need a start command (if the start function

in pause is disabled, it will be temporarily enabled to allow the

gate release).