E

N

G

L

IS

H

27

INSTALLATION

Installation of control unit and safety devices must be carried out

with power disconnected.

POWER SUPPLY

The control unit must be fed by a 230V 50Hz (120V - 50/60Hz

for the model

CITY1-120V

) electric line, protected by a

differential magnetothermal switch complying with the law

provisions in force.

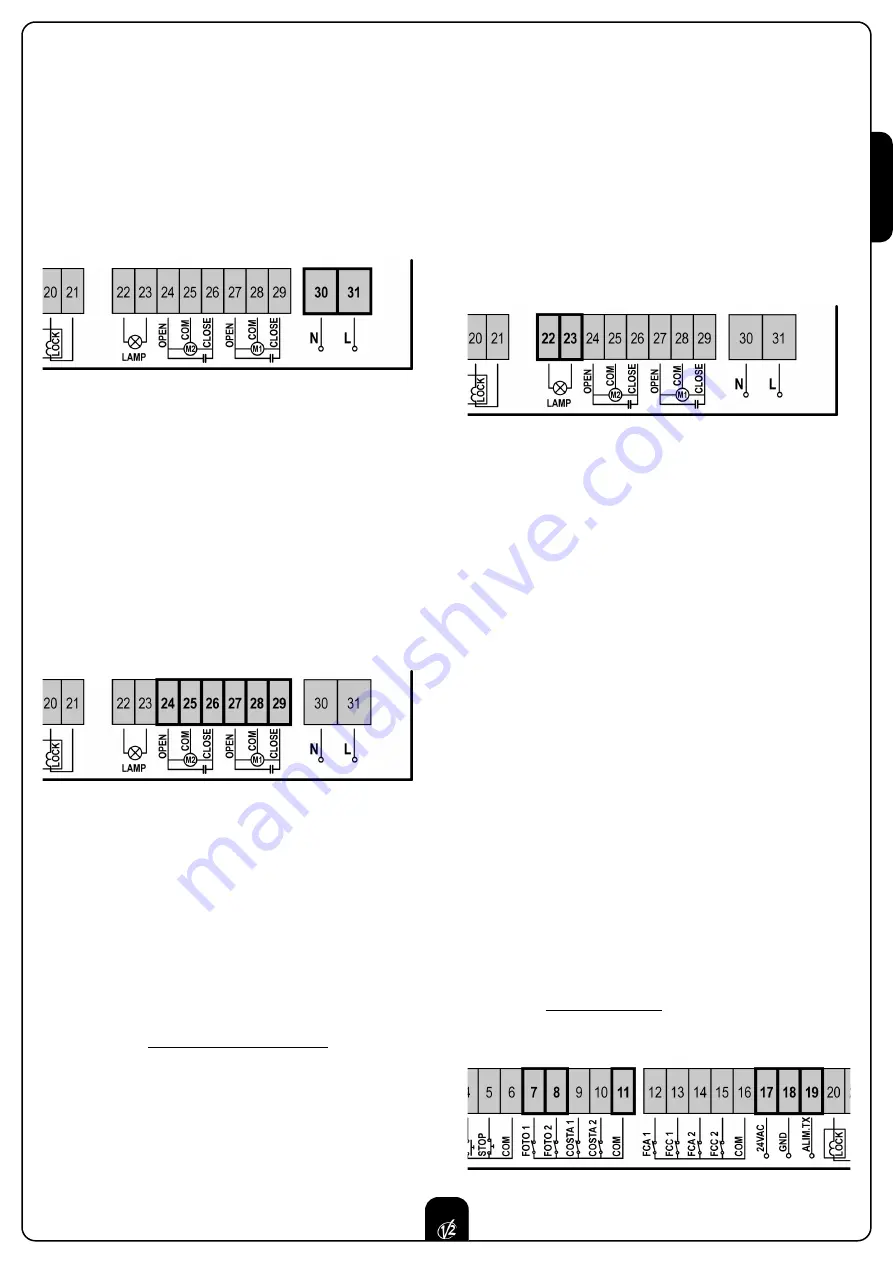

Connect power supply cables to terminals

30

and

31

of

CITY1

control unit.

MOTORS

CITY1

control unit can control one or two alternate current

asynchronous motors. If the control unit needs to control one

motor only, the latter must be connected to terminals of

motor 1.

Connect motor 1 cables as follows:

• opening cable to terminal

27

• closing cable to terminal

29

• common return cable to terminal

28

Connect motor 2 (if any) cables as follows:

• opening cable to terminal

24

• closing cable to terminal

26

• common return cable to terminal

25

CONTROL OF THE CORRECT ORDER OF CLOSING

LEAVES

If the leaves of the gate overlap during the closing phase, it is

necessary to connect the motor of the leaves that must start first

at the motor 1 terminals, and to arrange the delays (parameters

r.AP and r.Ch) so that collision is avoided.

If the control unit detects a wrong overlap order (leaf 1 gets to

the closing position before leaf 2), the gate is opened a little

again so that it can close correctly.

If the leaves do not overlap (e.g. in a double swing gate) set to

zero the opening door delay parameter in order to disable the

control of the right closing order.

WARNING (USING HYDRAULIC MOTORS):

• If using hydraulic motors, the following function could not

work properly: Soft start, Slowing down and Obstacle sensor.

In this case, such functions should be disabled from menu.

• Read carefully the working times self-learning procedure,

described in the paragraph “QUICK CONFIGURATION”,

paying particular attention to the points where the procedure

to be followed in case of disabled obstacle sensor is

described.

WARNING:

• In case it has not yet fitted, a start capacitor for each motor

is required; connect the start capacitor for motor 1 between

terminals

27

and

29

and start capacitor for motor 2 (if any)

between terminals

24

and

26

.

• In case motor 2 is not connected, set menu

tAP2

to zero.

BLINKER

CITY1

control unit provides for a 230V 40W (120V – 40W for

model

CITY1-120V

) blinker equipped with intermittence inside.

Connect blinker cables to terminals

22

and

23

of the control

unit.

PHOTOCELLS

The control unit considers two kinds of photocells, depending on

the terminal to which they are connected:

•

Photocell 1:

that is to say, photocells installed on the gate

inner side, which are active both during the opening and the

closing phase. When photocells 1 operate, the control unit

stops the doors; as soon as the photocell beam is free, the

control unit will open the gate completely.

•

Photocell 2:

that is to say, photocells installed on the

external gate side and which are active during the closing

phase only. When photocells 2 operate, the control unit

opens the gate immediately, without waiting for release.

CITY1

control unit supplies a 24VAC power supply to photocells

and it can perform a photocell operation test before starting the

gate opening phase. Photocell power terminals are

protected by an electronic fuse that stops current in case of

overload.

• Connect power supply cables of photocells transmitter

between terminals

19

and

18

of the control unit.

• Connect power supply cables of photocells receiver between

terminals

17

and

18

of the control unit.

• Connect receiver output of photocells 1 between terminals

7

and

11

of the control unit and receiver output of photocells

2 between terminals

8

and

11

of the control unit.

Use outputs having normally closed contact.

WARNING:

• if several couples of same kind photocells are mounted,

their outputs must be connected in series.

• In case of reflection photocells, power supply must be

connected to terminals

19

and

18

of the control unit to

carry out the operation test.