86

A permanent capacitor, impedance protected motor (no start

switch) on the circulator is required. The maximum allowable

amperage for this output is 2.2 amps, which limits the

allowable circulator size to 1/6 HP.

This type of system can use a small circulator to inject a high

BTU input into a relatively large system flow. Typically, the

injection pump need only deliver 1/6 to 1/4 of the system flow

for low temperature radiant panels if high temperature water

is available for injection. In small hydronic systems, the

smallest available circulator for variable speed injection may

be too large. It is important to properly size the injection pump

and use a globe valve on the return injection leg.

For proper injection pump sizing, the designer must know the

following information:

(See fig. b)

F

V

= Flow Rate (Injection Loop) in GPM

F

1

= Radiant (Secondary Loop) Flow Rate in GPM

T

1

= Boiler (Primary Loop) Supply Temperature

T

2

= Radiant (Secondary Loop) Supply Temperature

T

R

= Radiant (Secondary Loop) Return Temperature

T

D

= Radiant (Secondary Loop) Temperature

Differential (

T

2

-

T

R

)

Note:

All values are to be given at design

conditions. The formula used for sizing the

injection pump is shown below.

F

V

= (

F

1

x

T

D

)

/

(

T

1

-

T

R

)

Example:

If values at design conditions are:

F

1

= Radiant (Secondary) Flow = 30 GPM

T

1

= Boiler (Primary) Supply = 180°F

T

2

= Radiant (Secondary) Supply = 140°F

T

R

= Radiant (Secondary) Return = 120°F

T

D

= Radiant (Secondary) Differential = 20°F

To find the injection pump flow rate:

F

V

= (30 x 20)

/

(180 - 120)

F

V

= (600)

/

(60)

F

V

= 10 GPM

APPENDIX I

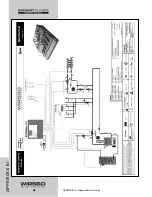

APPENDIX I - Variable Speed Injection Mixing

b

Direct Injection Mixing

“F

V

” to be calculated

Variable

Speed

Injection

Pump

Supply To LOW

Temperature Loop

T

2

F

1

Supply From HIGH

Temperature Loop

T

1

T

R

F

1

“DIRECT” INJECTION

F

V

F

V

T

D

Direct Injection

F

V

= (

F

1

x

T

D

) / (

T

1

-

T

R

)

Содержание SYSTEMpro 311

Страница 1: ...SYSTEMpro 311 Installation Manual...

Страница 44: ...PROGRAMMING THE ADJUST MENU B DHW SETTINGS 42 PROGRAMMING PROGRAMMING Step 1 Programming the Control...

Страница 52: ...PROGRAMMING THE ADJUST MENU D SNOW MELTING SETTINGS 50 PROGRAMMING PROGRAMMING Step 1 Programming the Control...

Страница 56: ...PROGRAMMING THE ADJUST MENU E BOILER OPERATION 54 PROGRAMMING PROGRAMMING Step 1 Programming the Control...

Страница 90: ...88 APPENDIX II APPENDIX II SYSTEMpro 311 Menu Tree...

Страница 91: ...89 APPENDIX II APPENDIX II SYSTEMpro 311 Menu Tree...

Страница 92: ...90 APPENDIX III APPENDIX III Application Drawings...

Страница 93: ...91 APPENDIX III APPENDIX III Application Drawings...

Страница 94: ...92 APPENDIX III APPENDIX III Application Drawings...

Страница 95: ...93 APPENDIX III APPENDIX III Application Drawings...

Страница 96: ...94 APPENDIX III APPENDIX III Application Drawings...

Страница 97: ...95 APPENDIX III APPENDIX III Application Drawings...

Страница 98: ...96 APPENDIX III APPENDIX III Application Drawings...

Страница 99: ...97 APPENDIX III APPENDIX III Application Drawings...

Страница 106: ......