268894-UIM-A-0407

2

Unitary Products Group

SPECIFIC SAFETY RULES AND PRECAUTIONS

1.

Only Natural gas or Propane (LP) gas are approved for use with

this furnace. Refer to the furnace rating plate or SECTION IV of

these instructions.

2.

Install this furnace only in a location and position as specified in

SECTION I of these instructions.

3.

A gas-fired furnace for installation in a residential garage must be

installed as specified in SECTION I of these instructions.

4.

Provide adequate combustion and ventilation air to the furnace

space as specified in SECTION VI of these instructions.

5.

Combustion products must be discharged outdoors. Connect this

furnace to an approved vent system only, as specified in SEC-

TION VI of these instructions.

6.

Test for gas leaks as specified in SECTION VIII of these instruc-

tions.

7.

Always install the furnace to operate within the furnace’s intended

temperature rise range. Only connect the furnace to a duct system

which has an external static pressure within the allowable range,

as specified on the furnace rating plate.

8.

When a furnace is installed so that supply ducts carry air circulated

by the furnace to areas outside the space containing the furnace,

the return air shall also be handled by duct(s) sealed to the fur-

nace casing and terminating outside the space containing the fur-

nace.

9.

It is permitted to use the furnace for heating of buildings or struc-

tures under construction. Installation must comply with all manu-

facturer’s installation instructions including:

•

Proper vent installation;

•

Furnace operating under thermostatic control;

•

Return air duct sealed to the furnace;

•

Air filters in place;

•

Set furnace input rate and temperature rise per rating plate

marking;

•

Means for providing outdoor air required for combustion;

•

Return air temperature maintained between 55ºF (13ºC) and

80ºF (27ºC);

•

The

air filter must be replaced

upon substantial completion of

the construction process;

•

Clean furnace, duct work and components upon substantial

completion of the construction process, and verify furnace-

operating conditions including ignition, input rate, temperature

rise and venting, according to the manufacturer’s instructions.

10. When installed in an Approved Modular Home or building con-

structed on-site, combustion air shall not be supplied from occu-

pied spaces.

11.

The size of the unit should be based on an acceptable heat loss

calculation for the structure. ACCA, Manual J or other approved

methods may be used.

SAFETY REQUIREMENTS

•

This furnace should be installed in accordance with all national

and local building/safety codes and requirements, local plumbing

or waste water codes, and other applicable codes. In the absence

of local codes, install in accordance with the National Fuel Gas

Code ANSI Z223.1/NFPA 54, National Fuel Gas Code, and/or

CAN/CGA B149.1 Natural Gas and Propane Installation Code

(latest editions). Furnaces have been certified to the latest edition

of standard ANSI Z21-47 • CSA 2.3.

•

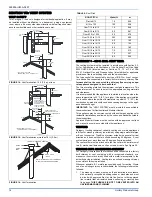

Refer to the unit rating plate for the furnace model number, and

then see the dimensions page of this instruction for return air ple-

num dimensions in Figure 4. The plenum must be installed

according to the instructions.

•

Provide clearances from combustible materials as listed under

Clearances to Combustibles in Table 1.

•

Provide clearances for servicing ensuring that service access is

allowed for both the burners and blower.

•

These models

ARE NOT

CSA listed or approved for installation

into a

Manufactured (Mobile) Home

.

•

This furnace is not approved for installation in trailers or recre-

ational vehicles.

•

Failure to carefully read and follow all instructions in this

manual can result in furnace malfunction, death, personal

injury and/or property damage.

•

Furnaces for installation on combustible flooring shall not be

installed directly on carpeting, tile or other combustible material

other than wood flooring.

•

Check the rating plate and power supply to be sure that the elec-

trical characteristics match. All models use nominal 115 VAC, 1

Phase, 60-Hertz power supply. DO NOT CONNECT THIS APPLI-

ANCE TO A 50 HZ POWER SUPPLY OR A VOLTAGE ABOVE

130 VOLTS.

•

Furnace shall be installed so the electrical components are pro-

tected from water.

•

Installing and servicing heating equipment can be hazardous due

to the electrical components and the gas fired components. Only

trained and qualified personnel should install, repair, or service

gas heating equipment. Untrained service personnel can perform

basic maintenance functions such as cleaning and replacing the

air filters. When working on heating equipment, observe precau-

tions in the manuals and on the labels attached to the unit and

other safety precautions that may apply.

•

These instructions cover minimum requirements and conform to

existing national standards and safety codes. In some instances

these instructions exceed certain local codes and ordinances,

especially those who have not kept up with changing residential

and modular home construction practices. These instructions are

required as a minimum for a safe installation.

COMBUSTION AIR QUALITY

(LIST OF CONTAMINANTS)

The furnace will require

OUTDOOR AIR

for combustion when the fur-

nace is located in any of the following environments.

•

Restricted Environments

•

Commercial buildings

•

Buildings with indoor pools

•

Furnaces installed in laundry rooms

•

Furnaces installed in hobby or craft rooms

•

Furnaces installed near chemical storage areas

•

Chemical exposure

The furnace will require

OUTDOOR AIR

for combustion when the fur-

nace is located in an area where the furnace is being exposed to the fol-

lowing substances and / or chemicals.

•

Permanent wave solutions

•

Chlorinated waxes and cleaners

•

Chlorine based swimming pool chemicals

•

Water softening chemicals

•

De-icing salts or chemicals

•

Carbon tetrachloride

•

Halogen type refrigerants

•

Cleaning solvents (such as perchloroethylene)

•

Printing inks, paint removers, varnishes, etc.

•

Hydrochloric acid

•

Cements and glues

•

Anti-static fabric softeners for clothes dryers

•

Masonry acid washing materials

When outdoor air is used for combustion, the combustion air intake duct

system termination must be located external to the building and in an

area where there will be no exposure to the substances listed above.

FIRE OR EXPLOSION HAZARD

Failure to follow the safety warnings exactly could result in serious

injury, death or property damage.

Never test for gas leaks with an open flame. Use a commercially

available soap solution made specifically for detection of leaks to

check all connections. A fire or explosion may result causing prop-

erty damage, personal injury or loss of life.