268894-UIM-A-0407

Unitary Products Group

19

Multi-story or common venting systems are permitted and must be

installed in accordance with the National Fuel Gas Code, ANSI Z223.1/

NFPA 54 and / or the CSA B149.1, Natural Gas and Propane Installa-

tion Codes, local codes, and the manufacturer's instructions.

Vent connectors serving Category I furnaces shall not be connected

into any portion of mechanical draft systems operating under positive

pressure.

Horizontal portions of the venting system shall be supported to prevent

sagging using hangers or perforated straps and must slope upwards

not less than 1/4" per foot (0.635 cm/m) from the furnace to the vent ter-

minal.

It is recommended that you follow the venting safety procedure below.

This procedure is designed to detect an inadequate ventilation system

that can cause the appliances in the area to operate improperly causing

unsafe levels of Carbon Monoxide or an unsafe condition to occur.

SECTION VIII: SAFETY CONTROLS

CONTROL CIRCUIT FUSE

A 3-amp fuse is provided on the control circuit board to protect the 24-

volt transformer from overload caused by control circuit wiring errors.

This is an ATO 3, automotive type fuse and is located on the control

board.

BLOWER DOOR SAFETY SWITCH

This unit is equipped with an electrical interlock switch mounted in the

blower compartment. This switch interrupts all power at the unit when

the panel covering the blower compartment is removed.

Electrical supply to this unit is dependent upon the panel that covers the

blower compartment being in place and properly positioned.

ROLLOUT SWITCH CONTROLS

These controls are mounted on the burner assembly. If the temperature

around the burners exceed the set point, the ignition control and the

gas valve are de-energized. The operation of this control indicates a

malfunction in the combustion air blower, heat exchanger or a blocked

vent pipe connection. Corrective action is required. These are manual

reset controls that must be reset before operation can continue.

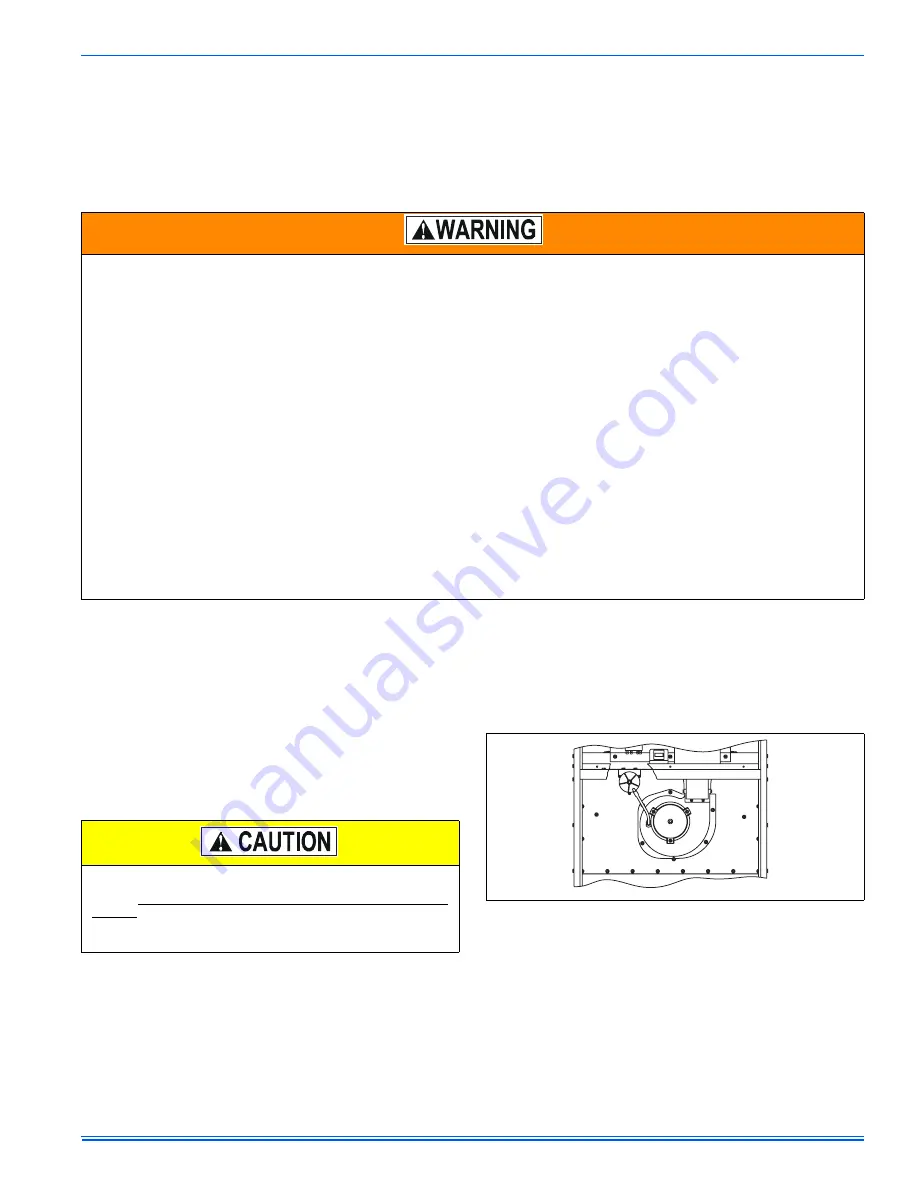

PRESSURE SWITCHES

This furnace is supplied with a pressure switch which monitors the flow

through the combustion air/vent piping system. This switch de-ener-

gizes the ignition control module and the gas valve if any of the follow-

ing conditions are present. Refer to Figure 26 for tubing connections.

1.

Blockage of vent piping or terminal.

2.

Failure of combustion air blower motor.

LIMIT CONTROLS

There is a high temperature limit control located on the furnace vesti-

bule panel near the gas valve. This is an automatic reset control that

provides over temperature protection due to reduced airflow. This may

be caused by:

1.

Dirty filter.

2.

If the indoor fan motor should fail.

3.

Too many supply or return registers closed or blocked off.

The control module will lockout if the limit trips five (5) consecutive

times. Control will reset and try again after one 1 hour.

CARBON MONOXIDE POISONING HAZARD

Failure to follow the steps outlined below for each appliance connected to the venting system being placed into operation could result in carbon

monoxide poisoning or death.

The following steps shall be followed for each appliance connected to the venting system being placed into operation, while all other appliances

connected to the venting system are not in operation:

1. Seal any unused openings in the venting system.

2. Inspect the venting system for proper size and horizontal pitch, as required in the National Fuel Gas Code, ANSI Z223.1/NFPA 54 or the

CSA B149.1, Natural Gas and Propane Installation Code and these instructions. Determine that there is not blockage or restriction, leak-

age, corrosion and other deficiencies which could cause an unsafe condition.

3. As far as practical, close all building doors and windows and all doors between the space in which the appliance(s) connected to the vent-

ing system are located and other spaces of the building.

4. Close fireplace dampers.

5. Turn on clothes dryers and any appliance not connected to the venting system. Turn on any exhaust fans, such as range hoods and bath-

room exhausts, so they are operating at maximum speed. Do not operate a summer exhaust fan.

6. Follow the lighting instructions. Place the appliance being inspected into operation. Adjust the thermostat so appliance is operating contin-

uously.

7. Test for spillage from draft hood equipped appliances at the draft hood relief opening after 5 minutes of main burner operation. Use the

flame of a match or candle.

8. If improper venting is observed during any of the above tests, the venting system must be corrected in accordance with the National Fuel

Gas Code, ANSI Z223.1/NFPA 54 and/or CSA B149.1, Natural Gas and Propane Installation Code.

9. After it has been determined that each appliance connected to the venting system properly vents when tested as outlined above, return

doors, windows, exhaust fans, fireplace dampers and any other gas-fired burning appliance to their previous conditions of use.

Main power to the unit must still be interrupted at the main power

disconnect switch before any service or repair work is to be done to

the unit. Do not rely upon the interlock switch as a main power dis-

connect.

Blower and burner must never be operated without the blower

panel in place.

FIGURE 26:

Pressure Switch Tubing Routing