268894-UIM-A-0407

Unitary Products Group

23

ADJUSTMENT OF TEMPERATURE RISE

The temperature rise, or temperature difference between the return air

and the heated supply air from the furnace, must be within the range

shown on the furnace rating plate and within the application limitations

as shown in Table 7.

After about 20 minutes of operation, determine the furnace temperature

rise. Take readings of both the return air and the heated air in the ducts,

about six (6) feet (1.83 m) from the furnace where they will not be

affected by radiant heat. Increase the blower speed to decrease the

temperature rise; decrease the blower speed to increase the rise.

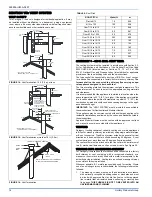

DIRECT DRIVE MOTORS

All direct-drive blowers have multi-speed motors. The blower motor

speed taps are located in the control box in the blower compartment.

Refer to Figure 29, and the unit-wiring label to change the blower

speed. To use the same speed tap for heating and cooling, the heat ter-

minal and cool terminal must be connected using a jumper wire and

connected to the desired motor lead. Place all unused motor leads on

Park terminals. Two are provided.

ADJUSTMENT OF FAN CONTROL SETTINGS

This furnace is equipped with a time-on/time-off heating fan control. The

fan on delay is fixed at 30 seconds. The fan off delay has 4 settings (60,

90, 120 and 180 seconds). The fan off delay is factory set to 120 sec-

onds. The fan-off setting must be long enough to adequately cool the

furnace, but not so long that cold air is blown into the heated space. The

fan-off timing may be adjusted by positioning the jumper on two of the

four pins as shown in Figure 29.

FURNACE CONTROL DIAGNOSTICS

The furnace has built-in, self-diagnostic capability. If a system problem

occurs, a blinking LED shows a fault code. The LED can flash red,

green or amber to indicate various conditions. It is located behind a

clear view port in the blower compartment door.

The control continuously monitors its own operation and the operation

of the system. If a failure occurs, the LED will indicate the failure code. If

the failure is internal to the control, the light will stay on continuously. In

this case, the entire control should be replaced, as the control is not

field repairable.

Flash sequence codes 1 through 10 are as follows: LED will turn “on”

for 1/4 second and “off” for 1/4 second. This pattern will be repeated the

number of times equal to the code. For example, six “on” flashes equals

a number 6 fault code. All flash code sequences are broken by a 2 sec-

ond “off” period.

SLOW GREEN FLASH:

Normal operation.

SLOW AMBER FLASH:

Normal operation with call for heat.

RAPID RED FLASH:

Twinning error, incorrect 24V phasing. Check

twinning wiring.

RAPID AMBER FLASH:

Flame sense current is below 1.5 microamps.

Check and clean flame sensor. Check for proper gas flow.

4

AMBER FLASHES:

The control board is recieving a “Y” signal from

the thermostat without a “G” signal, indicating improper thermostat wir-

ing.

1 RED FLASH:

This indicates that flame was sensed when there was

not a call for heat. With this fault code the control will turn on both the

inducer motor and supply air blower. A gas valve that leaks through or

is slow closing would typically cause this fault.

2 RED FLASHES:

This indicates that the normally open pressure

switch contacts are stuck in the closed position. The control confirms

these contacts are open at the beginning of each heat cycle. This would

indicate a faulty pressure switch or miswiring.

3 RED FLASHES:

This indicates the normally open pressure switch

contact did not close after the inducer was energized. This could be

caused by a number of problems: faulty inducer, blocked vent pipe, bro-

ken pressure switch hose or faulty pressure switch.

The temperature rise, or temperature difference between the return

air and the supply (heated) air from the furnace, must be within the

range shown on the furnace rating plate and within the application

limitations shown in Table 7 “RATINGS & PHYSICAL/ELECTRICAL

DATA”.

The supply air temperature cannot exceed the “Maximum Supply

Air Temperature” specified in these instructions and on the fur-

nace rating plate. Under NO circumstances can the furnace be

allowed to operate above the Maximum Supply Air Temperature.

Operating the furnace above the Maximum Supply Air Temperature

will cause premature heat exchanger failure, high levels of Carbon

Monoxide, a fire hazard, personal injury, property damage, and/or

death.

Do not energize more than one motor speed at a time or damage to

the motor will result.

FIGURE 29:

Furnace Control Board

PARK PARK

HI COOL

HEAT

EAC-H

L1

XFMR

NEUTRALS

HUM

TWIN

60

90

120

180

BLOWER

OFF

DELA

Y

Y/Y2

W

R

G

C

FAN OFF

ADJUSTMENT

JUMPER

RED-LOW

YELLOW-MED. LOW

BLACK-HI

BLUE-MED. HI