268894-UIM-A-0407

Unitary Products Group

15

2.

This furnace must be vented into a fire clay tile lined masonry

chimney only if a source of dilution air is provided, such as by com-

mon venting with a draft hood equipped water heater. If no source

of dilution air is available, Type B vent must be used, or masonry

chimney vent kit 1CK0603 or 1CK0604 must be used. Refer to the

instructions with the kit to properly apply these masonry chimney

kits.

3.

The chimney must extend at least three (3) ft (0.91 cm) above the

highest point where it passes through a roof of a building and at

least two (2) feet higher than any portion of the building with a hor-

izontal distance of ten (10) feet.

4.

The chimney must extend at least five (5) ft (1.5 cm) above the

highest equipment draft hood or flue collar.

HORIZONTAL SIDEWALL VENTING

For applications where vertical venting is not possible, the only

approved method of horizontal venting is the use of an auxiliary power

vent. Approved power venters are Fields Controls Model SWG-4Y or

the appropriate Tjernlund GPAK model. Follow all application and

installation details provided by the manufacturer of the power vent. This

unit may be horizontally vented using 4” (10.2 cm) diameter pipe with a

minimum length of 4.5 feet (1.37 m) and a maximum length of 34.5 feet

(10.82 m) with up to 4 elbows.

VENT PIPING ASSEMBLY

The final assembly procedure for the vent piping is as follows:

1.

Cut piping to the proper length beginning at the furnace.

2.

Deburr the piping inside and outside.

3.

Dry-fit the vent piping assembly from the furnace to the termination

checking for proper fit support and slope. Piping should be sup-

ported with pipe hangers to prevent sagging. The maximum spac-

ing between hangers is 5 feet (1.5 m).

4.

Assemble the vent piping from the furnace to the termination

securing the pipe connections with screws.

VENT CLEARANCES

IMPORTANT:

The vent must be installed with the following minimum

clearances as shown in Figure 19, and must comply with local codes

and requirements.

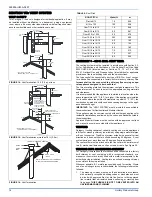

FIGURE 17:

Typical Sidewall Vent Application

FAN ASSISTED FURNACE

& WATER HEATER

FAN ASSISTED

FURNACES

VENT

PIPE

HOT

WATER

TANK

OPTIONAL

SIDEWALL

VENT SYSTEM

(field supplied)

EXTERIOR

VENT HOOD

FURNACE

FURNACE

FIGURE 18:

Typical Sidewall Vent and Termination Configuration

VENT PIPE

FLUE

PIPE

BURNER

ACCESS

PANEL

CELLAR

WALL

OPTIONAL

SIDEWALL

VENT SYSTEM

(field supplied)

TOP

COVER

BAROMETRIC

DAMPER