268894-UIM-A-0407

10

Unitary Products Group

Wire size and over current protection must comply with the National Electrical Code (NFPA-70-latest edition) and all local codes.

The furnace shall be installed so that the electrical components are protected from water.

Annual Fuel Utilization Efficiency (AFUE) numbers are determined in accordance with DOE Test procedures.

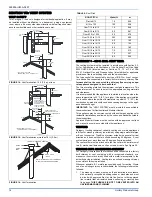

SUPPLY VOLTAGE CONNECTIONS

IMPORTANT:

The power connection leads and wiring box may be relo-

cated to the left side of the furnace. Remove the screws and cut wire tie

holding excess wiring. Reposition on the left side of the furnace and fas-

ten using holes provided.

1.

Provide a power supply separate from all other circuits. Install

overcurrent protection and disconnect switch per local/national

electrical codes. The switch should be close to the unit for conve-

nience in servicing. With the disconnect or fused switch in the OFF

position, check all wiring against the unit wiring label. Refer to the

wiring diagram, Figure 30, in this instruction.

2.

Remove the screws retaining the junction box cover. Route the

power wiring through the opening in the unit into the junction box

with a conduit connector or other proper connection. In the junc-

tion box there will be three (3) wires, a Black Wire, a White Wire

and a Green Wire. Connect the power supply as shown on the unit

wiring label on the inside of the blower compartment door or Fig-

ure 8. The black furnace lead must be connected to the L1 (hot)

wire from the power supply. The white furnace lead must be con-

nected to neutral. Connect the green furnace lead (equipment

ground) to the power supply ground. An alternate wiring method is

to use a field provided 2” (5.1 cm) x 4” (10.2 cm) box and cover on

the outside of the furnace. Route the furnace leads into the box

using a protective bushing where the wires pass through the fur-

nace panel. After making the wiring connections replace the wiring

box cover and screws.

3.

The furnace's control system requires correct polarity of the power

supply and a proper ground connection. If the power supply polar-

ity is reversed, the control board will flash nine (9) times. The fur-

nace will not operate until the polarity is corrected. Refer to

"FURNACE DIAGNOSTICS" section of the “User’s Information,

Maintenance, & Service Manual” provided with this furnace for

symptoms of reversed power supply polarity.

LOW VOLTAGE CONTROL WIRING CONNECTIONS

Install the field-supplied thermostat by following the instructions that

come with the thermostat. With the thermostat set in the OFF position

and the main electrical source disconnected, connect the thermostat

wiring from the wiring connections on the thermostat to the terminal

board on the ignition module, as shown in Figure 9. Electronic thermo-

stats may require the common wire to be connected as shown in Figure

9. Apply strain relief to thermostat wires passing through cabinet. If air

conditioning equipment is installed, use thermostat wiring to connect

the Y and C terminals on the furnace control board to the proper wires

on the condensing unit (unit outside).

TABLE 7:

Ratings & Physical / Electrical Data

Input

Output

Nominal

Airflow

Cabinet Width

Total Unit

Amps

AFUE

Air Temp. Rise

MBH

kW

MBH

kW

CFM

m

3

/min

In.

cm

°F

°C

40

11.7

32

9.4

1200

34.0

14-1/2

36.8

9.0

80.0

20-50

11-28

60

17.6

48

14.1

1200

34.0

14-1/2

36.8

9.0

80.0

25-55

13-31

80

23.5

64

18.8

1200

34.0

14-1/2

36.8

9.0

80.0

35-65

19-36

80

23.5

64

18.8

1600

45.3

17-1/2

44.5

12.0

80.0

25-55

13-31

80

23.5

64

18.8

1600

45.3

21

53.3

12.0

80.0

25-55

13-31

100

29.3

80

23.4

1200

34.0

17-1/2

44.5

12.0

80.0

40-70

22 39

100

29.3

80

23.4

1600

45.3

21

53.3

12.0

80.0

25-55

13-31

100

29.3

80

23.4

2000

56.6

21

53.3

14.0

80.0

25-55

13-31

115

33.7

92

26.9

1600

45.3

21

53.3

12.0

80.0

35-65

19-36

115

33.7

92

26.9

2000

56.6

21

53.3

14.0

80.0

30-60

17-33

130

38.1

104

30.5

2000

56.6

24-1/2

62.2

14.0

80.0

40-70

22-39

Input

Max. Outlet

Air Temp

Blower

Blower Size

Max

Over-Current

Protect

Min. wire Size

(awg) @ 75 ft

one way

Operation

Weight

MBH

kW

°F

°C

Hp

Amps

In.

cm

LBS

Kg

40

11.7

150

65.6

1/3

6.2

10 x 8

25.4 x 20.3

20

14

100

45.4

60

17.6

155

68.3

1/3

6.2

10 x 8

25.4 x 20.3

20

14

110

49.9

80

23.5

165

73.9

1/3

6.2

10 x 8

25.4 x 20.3

20

14

120

54.4

80

23.5

160

71.1

3/4

11.0

11 x 10

27.9 x 25.4

20

14

130

59.0

80

23.5

160

71.1

3/4

11.0

10 x 10

25.4 x 25.4

20

14

130

59.0

100

29.3

170

76.7

1/2

7.0

10 x 8

25.4 x 20.3

20

14

125

56.7

100

29.3

155

68.3

3/4

11.0

11 X 10

27.9 x 25.4

20

14

140

63.5

100

29.3

155

68.3

1

12.2

11 x 11

27.9 x 27.9

20

12

140

63.5

115

33.7

165

73.9

3/4

11.0

11 x 10

27.9 x 25.4

20

14

150

68.0

115

33.7

160

71.1

1

12.2

11 x 11

27.9 x 27.9

20

12

150

68.0

130

38.1

170

76.7

1

12.2

11 x 11

27.9 x 27.9

20

12

160

72.6

FIGURE 8:

Electrical Wiring

NEUTRALS

EAC

COOL

HEA

T

HUM

PA

RK

PA

RK

L1

XFMR

Y W R G C

L1

HOT

N

GRN

GRN

WHT

BLK

JUNCTION

BOX

BLK/BLK

WHT/WHT

GRN/GRN

WIRING INSIDE

JUNCTION BOX

VENT PIPE

CLASS 2 SYSTEM

CONTROL WIRING

TO THERMOSTAT

FLUE CHASE

DOOR

SWITCH

BURNER COMPARTMENT

BLOWER COMPARTMENT

IGNITION MODULE

TRANSFORMER