268894-UIM-A-0407

12

Unitary Products Group

IMPORTANT:

Some electronic thermostats do not have adjustable heat

anticipators. They may have other type cycle rate adjustments. Follow

the thermostat manufacturer's instructions.

The 24-volt, 40 VA transformer is sized for the furnace components

only, and should not be connected to power auxiliary devices such as

humidifiers, air cleaners, etc. The transformer may provide power for an

air conditioning unit contactor.

ACCESSORY CONNECTIONS

The furnace control will allow power-switching control of various acces-

sories. Refer to Figure 10, for connection details.

ELECTRONIC AIR CLEANER CONNECTION

Two 1/4” (0.64 cm) spade terminals (EAC and NEUTRAL) for electronic

air cleaner connections are located on the control board. The terminals

provide 115 VAC (1.0 amp maximum) during circulating blower opera-

tion.

HUMIDIFIER CONNECTION

Two 1/4” (0.64 cm) spade terminals (HUM and NEUTRAL) for humidi-

fier connections are located on the control board. The terminals provide

115 VAC (1.0 amp maximum) during heating system operation.

SECTION VI: TWINNING AND STAGING

In applications where more heating capacity or more airflow capacity is

needed than what one furnace can deliver, twinning can be used to

make two furnaces operate in tandem. When two furnaces are installed

using the same duct system, it is very important that the two furnace cir-

culating air blowers operate in unison. If one blower starts before the

second blower, the duct system will become pressurized and the blower

on the second furnace will turn backwards causing the second furnace

to overheat, resulting in damage to the furnace. Twinning is used to

make two furnaces operate in tandem, using one duct system, one

room thermostat and causing both furnaces to turn on and off simulta-

neously.

TWINNING DUCT SYSTEM

Twinned furnaces must only be applied on a common duct system. A

single air supply plenum must be used for both furnaces and coil(s).

Separate plenums and supply ducts systems cannot be utilized. A sin-

gle return air plenum, common to both furnaces must be used. It is sug-

gested that a return platform be utilized, with bottom air entrance into

each furnace. If a side entrance returns system is used, the common

return duct must be divided equally so as to supply each furnace with

an equal amount of return air.

Both furnaces must be identical models in both heating capacity and

CFM capacity. Both furnaces must be operated on the same motor

speed tap. See typical application, Figure 11.

If furnace staging is desired with two single stage furnaces on a com-

mon duct, where the gas burner on the first furnace operates on W1

and the gas burner on the second furnace operates on W2, then the

use of an air-mixing device in the plenum to mix the air from both fur-

naces is strongly recommended. The mixing device must be installed

before any ducts that supply air to occupied spaces. Twinning causes

both indoor fans to operate simultaneously. If a mixing device is not

used, any ducts that are connected down stream from the furnace that

operates on W2, will be supplying cold air in the Heating mode to the

occupied spaces unless W2 is energized.

IMPORTANT:

When two furnaces are twinned, typical system total air-

flow will be approximately 85% of additive individual furnaces, i.e., two

2000 CFM units will yield a total 3400 CFM.

GAS PIPING

Furnace gas supplies must be provided as specified with these instruc-

tions. Since the furnaces are side by side, with no space between, gas

supplies must enter on the right and left respectively. All gas piping

must be in accordance with the national fuel gas code, ANSI Z223.1,

latest edition, and/or all local code or utility requirements.

TWINNING

In applications where more heating capacity or more airflow capacity is

needed than what one furnace can deliver, twinning can be used to

make two furnaces operate in tandem, using one duct system and one

room thermostat. When one duct system is used for two furnaces, it is

necessary that the two blowers operate in unison. The twinning function

of the board in this furnace ensures that both blowers turn on and off

simultaneously, and operate on the same blower speed.

Set the heat anticipator in the room thermostat as shown below. Set-

ting it lower will cause short cycles. Setting it higher will cause the

room temperature to exceed the setpoint.

Single Stage Thermostat

.4 Amps

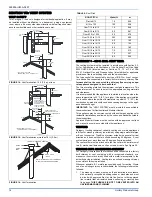

FIGURE 10:

Accessory Connections

Before installing the relay and wiring, disconnect electrical power to

both furnaces. Failure to cut power could result in electrical shock

or equipment damage.

The relay must not be installed in any location where it could be

exposed to water. If the relay has been exposed to water in any

way, it must not be used.

115 VOLT

HUMIDIFER

115 VOLT

ELECTRONIC

AIR CLEANER

EAC HOT

HUM. HOT

BLK

WHT

EAC

HUM

NEUTRALS

SWITCHED

CIRCUITS

BLK

WHT

FIGURE 11:

Typical Twinned Furnace Application

If a return duct is connected to only one furnace (with a connection

between the two furnaces) an imbalance in the airflow will occur

and the furnace furthest from the return plenum will overheat.

VENT PIPE

ELECTRICAL

SUPPLY

GAS SUPPLY

(BOTH SIDES)

1 COIL FOR

EACH FURNACE

COMMON

SUPPL

Y

PLENUM

SUPPLY

AIR