CONVEYOR BELT TENSION

The conveyor belt of the Ultra-Max Conveyor Oven

does not have a tension adjustment. If the belt

becomes too loose, a link will have to be removed

to tighten. A belt that is too tight will also cause

operational problems due to excessive drag. We

suggest that you have a qualifi ed service technician

perform this adjustment.

CAUTION

Careful consideration should be exercised prior

to removing a belt link because a belt that is too

tight will impede the smooth operation of the

conveyor.

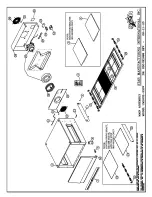

CONVEYOR BELT LINK REMOVAL

An entire link can be removed with the conveyor

assembly either in or out of the oven. This may be

necessary as the belt stretches after continuous

use. Following are the necessary steps for removing

links:

1. Move the splice clips to either end of the oven for

easy access.

2. Unhook the splice clips using long nose pliers.

3. Unhook the full link to be removed and slide it out.

Do not discard the link removed as it may be used

for making spare splice clips.

4. Reconnect the inside splice clips.

5. Reconnect the outside splice clips.

6. Replace all parts removed from the oven.

7. Straighten any bent wires to ensure smooth

sprocket engagement.

Remove the outside master links on the right

and left sides of the conveyor belt. Remove the

center splice clips next.

Unhook the end loop and pull up on the link

section. Save this link as it may be used for

making splice clips.

Check the orientation of the splice clips (the hooks

should be up). The belt shown is the top section,

ready for left-to-right travel.