DISPLAY INFORMATION

When operating the oven, there are three levels of

access:

1. Store Level - General employees would know

these functions and how to change them. While

the oven is running, enter this mode by holding the

DOWN and UP arrows (

) simultaneously for

four seconds. The TIME display goes blank and

the TEMP setpoint is displayed. Adjust with the

DOWN or UP arrows. The ENTER button (

)

toggles between TIME and TEMP. The parameter

that can be adjusted is displayed, the other is

blank. When TIME and TEMP are adjusted as

needed, wait fi ve seconds and SAVE is displayed.

The values are accepted and the controller begins

controlling to these new values. The conveyor

continues to operate at the same speed until a

new value is accepted. The temperature control

output should be OFF during changes.

2. Manager Level - This is a lock so that TIME and

TEMP cannot be changed even at the Store Level.

While the oven is running, enter this mode by

holding the DOWN and UP arrows simultaneously

for 4 seconds. The TIME display goes blank and

the TEMP setpoint is displayed. Release the

UP arrow and continue to hold the DOWN arrow

for an additional 4 seconds. The TEMP display

shows LOC as the TIME display shows nO, which

indicates that the TIME/TEMP parameters can be

changed

after reaching the STORE level. yES indicates

that the parameters cannot be changed even after

entering the STORE level. The LOC setting can

be toggled using the ENTER button (

).

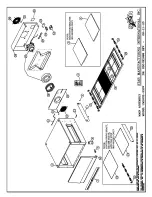

ADDITIONAL FUNCTIONS

The conveyor belt direction and the temperature

display can be changed on the conveyor oven

by a qualifi ed technician. To change the belt

direction, the technician must reverse the motor

direction and rotate the conveyor belt for proper

oven function. A technician can also change the

temperature display from Fahrenheit to Celsius.

These changes can be made by the technician

during the start-up/check-out or at a later date.

ERROR CODES

Error codes will display as fl ashing text messages for

diagnostic purposes. Any temperature or thermocouple

error should turn the temperature output OFF and leave

the conveyor running at the same speed. The belt

error should turn the temperature output OFF. The

speed error should display when the motor is unable

to settle at the chosen speed. This might occur if a

fast speed is chosen that the motor is unable to spin

fast enough to achieve. The speed signal output will

remain the same but the display will fl ash the error

message.