UBI EasyCoder 501 – Service Manual

26

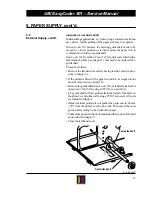

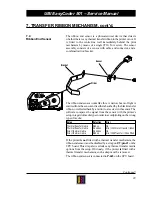

5. PAPER SUPPLY, cont'd.

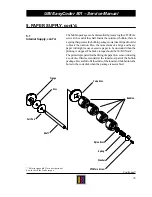

The bobbin package can be dismantled by removing the #T20 Torx

screw at the end of the shaft. Inside the outermost bobbin, there is

a spring that presses the bobbin package towards a felt pad in order

to break the rotation. Else, the momentum of a large and heavy

paper roll might cause excessive paper to be unwound when the

printing is stopped. The brake torque should be 50

±

20 Nmm

1

.

The printer is prepared for the fitting of a paper-low sensor in having

a code disc fitted as standard at the innermost part of the bobbin

package. Be careful to fit the studs of the innermost bobbin into the

holes in the code disk when the package is assembled.

5.1

Internal Supply, cont'd.

Continued!

1

/. Refer to Appendix 2 for a description of

how to check the brake torque.

Flange

Nylon Disc

#T20 Torx Screw

Washer

Spring

Shaft

Felt Pad

Disc

Bobbins

Code Disc

Содержание EasyCoder 501 SA

Страница 214: ...UBI EasyCoder 501 Service Manual 214 NOTES...