53

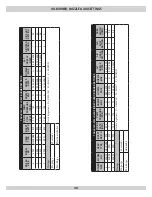

COMBUSTION

1.

Nozzles- Not all manufacturers’ nozzles perform the same.

A.

Table 15

in the

Burner Settings

section shows the nozzles

that passed rigorous testing in our laboratory.

Fuel leaks - Any fuel leak between the pump and the nozzle

B.

will be detrimental to good combustion results. Look for wet

surfaces in the air tube, under the ignitor, and around the air

inlet. Any such leaks should be repaired as they may cause er-

ratic burning of the fuel and in the extreme case may become a

fire hazard.

Dirt - A fuel filter is required to prevent clogging the nozzle

C.

or nozzle strainer and produce a poor spray pattern from the

nozzle.

Water - Water in the fuel in large amounts will stall the fuel

D.

pump. Water in the fuel in smaller amounts will cause exces-

sive wear on the pump, but more importantly water doesn’t

burn. It chills the flame and causes smoke and unburned fuel

to pass out of the combustion chamber and clog the flue ways

of the boiler.

Cold Oil - If the oil temperature approaching the fuel pump

E.

is 40°F or cooler, poor combustion or delayed ignition may

result. An outside fuel tank that is above grade or has fuel lines

in a shallow bury may be the cause.

High Altitude Installation - Air openings must be increased at

F.

higher altitudes. Use combustion analyzer and set to 11.5% for

an initial setting.

Start up noise - Late ignition is the cause of start up noises. If it

G.

occurs recheck for electrode settings, flame shape, air or water

in the fuel lines.

Shut-down noise - Post Purge timed 15 seconds should elimi-

H.

nate shut-down noise.

OIL PRIMARY CONTROL

2.

Burner (control) will not come on.

A.

No power to control.

I.

Control is in lockout or restricted mode. Press reset button

II.

for 30 seconds to exit lockout. If control has recycled three

times within the same call for heat, it will enter into restricted

mode. To reset from restricted mode, refer to page 41 for more

details.

CAD Cell seeing light.

III.

CAD assembly defective.

IV.

Burner (control) will light, then shut down after a short time,

B.

then restart after one (1) minute.

CAD cell is defective.

I.

Air leaking into oil line causing flame out.

II.

Defective nozzle causing flame to be erratic.

III.

Excessive airflow or draft causing flame to leave burner head.

IV.

Excessive back pressure causing erratic flame.

V.

Control locks out after trial for Ignition. (TFI)

C.

No oil to burner.

I.

Shortened electrodes

II.

Clogged nozzles.

III.

Airflow too high.

IV.

Ignitor module defective.

V.

CAD cell defective.

VI.

Oil valve stuck open or closed.

VII.

TrOUBLeSHOOTiNg

NOTICE

To isolate fuel problems: disconnect the fuel system and fire out

of an auxiliary container of clean, fresh, warm #2 fuel oil from

another source. If the burner runs successfully when drawing out

the container then the problem is in the fuel or fuel lines.

NOTICE

If flame is not established within 15 seconds of oil valve actua-

tion (known as Trial For Ignition or TFI) lockout will occur.

Lockout is indicated by a steady on red LED located on the oil

primary control.

NOTICE

Lockout without retries will occur if the flame is lost three times

during one call for heat. This is indicated by a steady on red and

amber LED’S