13

Remove Crate

1.

Remove all fasteners at crate skid.

A.

Lift outside container and remove all other inside protective

B.

spacers and bracing. Remove burner and miscellaneous parts

boxes.

Remove Boiler from skid

2.

. Boiler is secured to base with 4

screws. Remove all securing hardware.

Move boiler into permanent position by sliding or walk-

3.

ing into place.

!

CAUTION

Do not drop boiler. Do not bump boiler jacket against floor.

Open the burner swing door

4.

. Throughout this manual, you

will be instructed to open and close the burner swing door for vari-

ous reasons. There is a proper and improper method to closing and

securing the burner swing door opened for inspection, cleaning or

field service.

Loosen and remove non-hinged side latching hardware.

A.

Remove hinged side latching hardware.

B.

Door can be swung to the fully open position, approximately.

C.

90 to 120 degrees, with the burner mounted providing that

there is 22” of clearance to the adjacent wall.

!

CAUTION

If burner door is lifted when opened, it can come off it’s hinges.

NOTICE

If reduced clearance prevents the door from opening fully, one

of the following can provide full access:

Burner can be removed to allow full rotation of door.

Door with burner mounted can be lifted off hinges and set aside

during servicing.

The door mounting hardware is reversible from left side hinge (as

shipped) to right side hinge. To reverse the hinge arrangement:

(See Figure #2C)

Lift door off mounting eye bolts and set aside.

Remove mounting eye bolts from left side.

Move door mounting eye bolts to right side.

Tighten both sets of hardware.

Lift door and place integral cast hinge pins on door into slotted

mounting bracket holes.

Inspect Swing door insulation and rope gasket.

5.

Inspect fiber rope located on the swing door. The rope must

A.

be evenly distributed around the perimeter of the door groove

and cannot bunch or overhang. There must not be a gap where

the two ends of the rope meet. Repair or replace if the rope is

damaged or if there is a gap between the ends.

Inspect burner swing door insulation for damage.

B.

By design, the combustion chamber and raised portion be-

C.

tween the 2nd and 3rd pass flue ways should make an impres-

sion in door insulation.

Do not close and secure door at this time.

D.

Figure 2C - reversible Hinge

NOTICE

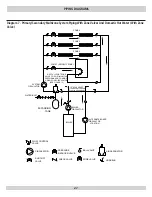

For the purpose of these instructions, all pipe connections shall

use pipe dope or Teflon tape to assure water tight connections

unless otherwise instructed. For steps 6 thru 16, refer to Figure

#6.

Open accessory carton

6.

and remove contents. Identify the

components using the illustrations throughout this section as

applicable to your installation.

Remove top panel

7.

. Remove sheet metal screws securing the top

panel to jacket rear panel. Slightly lift rear of jacket top panel away

from side panels. If the boiler is equipped with a lifting hinged

front panel, push the top panel toward the rear of the boiler and

lift off of side panels to gain access to internal control panel.

Locate the shorter of the two 1 1/4” nipples

8.

. Thread thru

the insulation slot into supply port in rear of boiler. Locate the 1

1/4” x 90° elbow and assemble onto nipple. Be sure connections

are

tight

and outlet is facing directly up. See

Figure #3

.

Locate the longer of the two 1 1/4” nipples

9.

. Assemble onto

elbow. See

Figure #3

.

ASSeMBLiNg THe BOiLer

NOTICE

It is recommended that hinges should be on same side as flexible

oil line in order to swing the door open.