45

IF CONTROLS DO NOT MEET REQUIREMENTS

7.

replace control and repeat checkout procedures.

!

CAUTION

Do not run boiler unattended until the following procedure is

completed.

NOZZLES AND ELECTRODES

8.

: Use the proper size,

spray angle, and spray pattern nozzle. Refer to the recommend-

ed nozzle selection charts at the end of this manual. To install a

nozzle, remove the nozzle line electrode assembly, if necessary

remove the retention ring assembly, and then install and tighten

the nozzle. Be careful not to damage the electrode insulators or

bend the electrode tips. After installing the nozzle, reassemble

the nozzle line electrode assembly and set the electrode tip

spacing. The electrode tip spacing may need to be set prior to

reassembling the nozzle line electrode assembly. Refer to the

figures on the following pages for setting the electrode tip spac-

ing on Beckett.

FINAL BURNER ADJUSTMENTS

9.

: Final burner adjust-

ments must be made using combustion test instruments. Initial

settings for the burner are shown at the back of this manual.

Set the burner accordingly. Check the draft breech to verify

A.

that it is between 0.00” WC and -0.05” WC, or otherwise

adjust the draft to -0.05” WC (or less than zero.) After operat-

ing 10 minutes to warm up the boiler, use the combustion test

equipment to take a smoke reading in the flue pipe between

the boiler and the draft regulator. The smoke reading should

be zero to a trace (Shell Bacharach Scale). At times a new boil-

er requires more than 10 minutes to burn clean due to the oil

film on the new heat exchanger. If the smoke reading is zero,

gradually close the burner’s air adjustment to obtain a smoke

reading showing a trace smoke reading. Once the smoke read-

ing is a trace, measure the CO2 and as an insurance margin

increase the air to sufficiently reduce the CO2 by 1/2% to 1%.

If a clean fire cannot be obtained, it will be necessary to verify

B.

the burner head alignment. If the fire continues to be smoky,

replace the nozzle.

Once the burner is completely adjusted, the burner should be

C.

started and stopped several times to assure good operation

with no fluttering or rumbling. Verify that there are no oil

leaks and then record the nozzle size, oil pressure, combustion

readings, and air settings on a tag or label that can be attached

to the burner or, boiler.

CHECk OPTIONAL LOW WATER CUT OFF

10.

CONTROL AND OPTIONAL MANUAL RESET

TEMPERATURE LIMIT

. These are optional kits. Please see

instructions for installation, startup check out and maintenance.

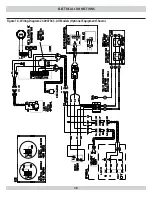

Figure #23A

shows where these optional kits are plugged into

the control panel.

Figure 23A

CHECk THERMOSTAT OPERATION:

11.

The thermostat

location has an important effect on the operation of the boiler sys-

tem. Be sure to follow the instructions included with your ther-

mostat. Typically, the thermostat is located about five feet above

the floor on an inside wall. The thermostat should be located to

sense average room temperature, so avoid the following:

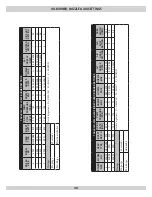

TABLE 13: THERMOSTAT LOCATIONS TO AVOID

DEAD

SPOTS

HOT SPOTS

COLD SPOTS

Behind doors

Concealed pipes

Concealed pipes

or ducts

Fireplace

TV sets

Stairwell drafts

Corners &

alcoves

Radios

Door drafts

Lamps

Unheated room on

other side of wall

Direct sunlight

Kitchens

Make certain: once the room temperature reaches the selected tem-

perature setting, the thermostat should turn the boiler’s burner off,

and once the room temperature falls a few degrees the boiler starts

operating again.

OPerATiNg THe BOiLer - SYSTeM STArT-UP