button 3 to select the Sub-Area screen

(

2.

Use the InfoCenter buttons (

) to

perform the following actions:

•

Press button 1 to return to the Home screen.

•

Press button 2 to navigate to the Total Area

screen.

•

Press button 3 to change the active sub-area

to the next sub-area.

•

Press and release

button 4 to change the

active sub-area to the previous sub-area.

Press and hold

the button 4 to reset area

and volume sprayed for the active sub-area.

•

Press button 5 to exit the menu bar.

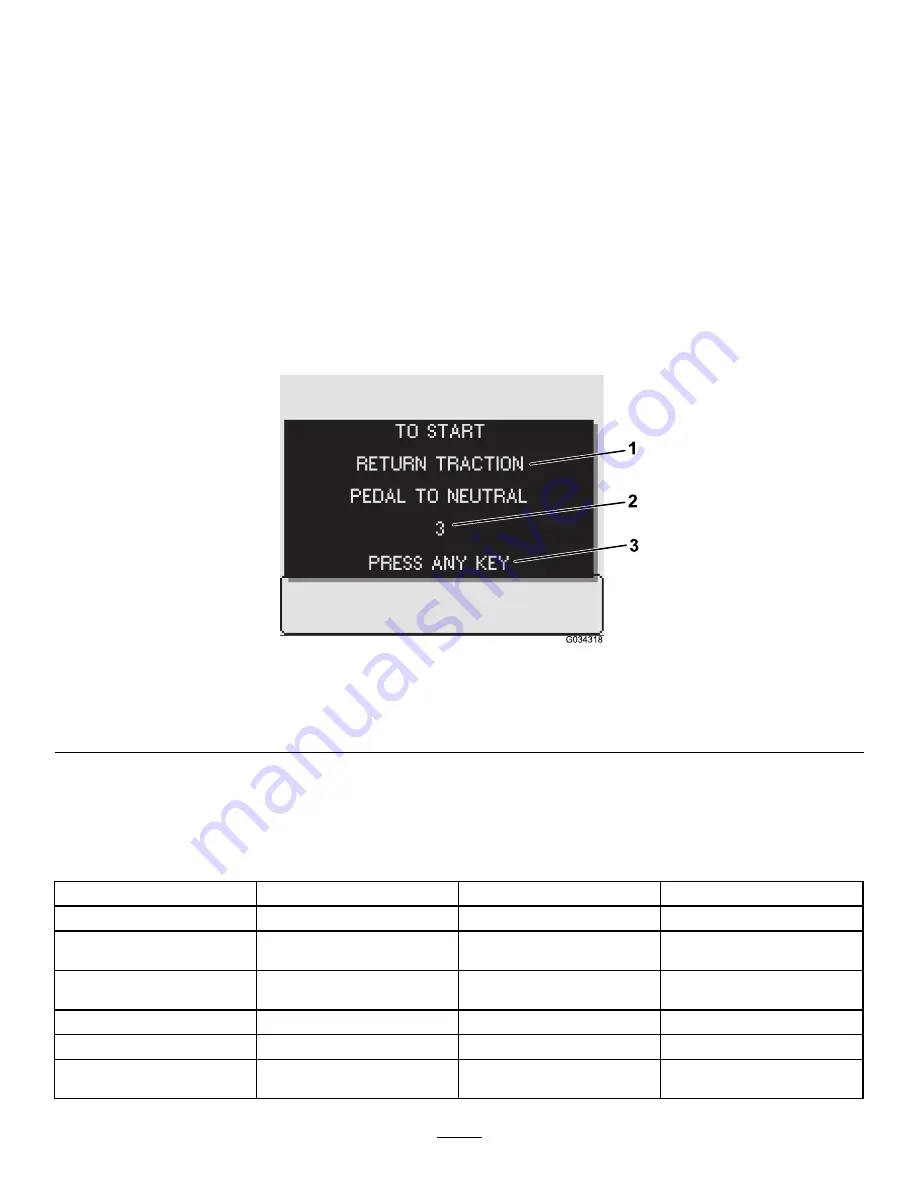

InfoCenter Advisories

Operator advisories automatically display on the InfoCenter screen when a machine function requires additional

action. For example, if you attempt to start the engine while pressing the traction pedal, an advisory displays,

indicating that the traction pedal must be in the N

EUTRAL

position.

For each advisory that occurs, there is a condition (e.g., start prevent, engine stopped), an advisory code

(number), a qualifier (the cause of the advisory displayed), and a display text (what the advisory displays as text

on the screen) as shown in

.

g034318

Figure 78

1.

Display text

3.

Press any key on the InfoCenter to clear the text from the

display screen.

2.

Advisory code

Note:

Advisories do not log into the fault log.

Note:

You can clear an advisory from the display screen by pressing any of the InfoCenter keys.

Refer to the following table for all the InfoCenter advisories:

Advisories Table

Condition

Code

Qualifier

Display Text

Start Prevented

2

Pump switch active

To start, turn pump off

Start Prevented

3

Not in N

EUTRAL

To start, return traction pedal to

neutral

Start Prevented

4

Out of seat

To start, must be seated or set

the parking brake

Start Prevented

5

Starter engage timeout

To start, rest starter

Start Prevented

6

Rinse pump active

To start, turn off rinse pump

Engine Stopped

102

Out of seat

Engine stop due to operator out

of seat

28