17

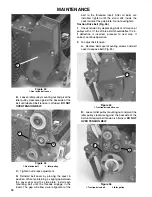

MAINTENANCE

Figure 29

1. Foam element 2. Paper element

1

2

A.

WASH foam element in a solution of liquid

soap and warm water. Squeeze to remove dirt,

but do not twist because foam may tear.

B.

DRY by wrapping in a clean rag. Squeeze

rag and foam element to dry.

C.

SATURATE element with clean engine oil.

Squeeze element to remove excess oil and to

distribute oil thoroughly. An oil damp element is

desirable.

4.

When servicing foam element, check condition of

paper element. Clean or replace as required.

5.

Reinstall foam element, paper element and air

cleaner cover.

IMPORTANT: Do not operate engine without air

cleaner element because extreme engine wear and

damage will likely result.

REPLACING SPARK PLUG

Use an

NGK BPR 5ES

spark plug or equivalent.

Correct air gap is 0.028" - 0.032". Remove plug after

every 100 operating hours and check its condition.

1.

Pull wire off spark plug.

2.

Clean around spark plug and remove plug from

cylinder head (Fig. 30)

Figure 30

1. Spark plug

1

IMPORTANT: Replace a cracked, fouled, or dirty

spark plug. Do not sand blast, scrape, or clean

electrodes because engine damage could result

from grit entering cylinder.

3.

Set air gap at 0.028"- 0.032" (Fig. 31). Install

correctly gapped spark plug and tighten firmly to

17 ft-lb.

Figure 31

0.028" - 0.032"

CLEANING FUEL FILTER

Initially, clean fuel filter after the first 20 hours of

operation; thereafter clean after every 50 hours

operation.

1.

Close fuel shut off valve and unscrew bowl from

filter body (Fig. 32).

Figure 32

1. Shut off valve

2. Bowl

2

1

2.

Clean bowl and filter in clean gasoline and reinstall.

ADJUSTING BELTS

Make sure belts are properly tensioned to assure

proper operation of the machine and unnecessary

wear. Check belts frequently.

Reel Drive belt (Fig. 34)

1.

Check tension by depressing belt at mid span of

pulleys with 4

±

1 lbs. of force. Belt should deflect 1/4 in.

If deflection is incorrect, proceed to next step. If

correct, continue operation.

2.

To adjust belt tension:

A.

Remove belt cover mounting screws and belt

cover to expose belt (Fig. 33).