,*74(

26(

Each time adjusting screw is rotated one click

clockwise, bedknife moves .0007" closer to reel.

" ! #

Check for light contact at other end of reel using

paper and adjust as required.

After adjustment is accomplished, check to see if

reel can pinch paper when inserted from the front and

cut paper when inserted at a right angle to the bedknife

(Fig. 10). It should be possible to cut paper with

minimum contact between the bedknife and the reel

blades. Should excessive reel drag be evident (more

than 7 inch pounds) it will be either necessary to

backlap or re-grind the cutting unit to achieve the

sharp edges needed for precision cutting (see Toro

reel sharpening manual).

! !

Verify that rear roller is level and that bedknife to

reel contact is correct. Tip mower back on handle to

expose front and rear rollers and bedknife.

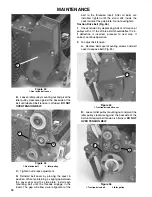

Loosen locknuts securing heightĆofĆcut arms to

heightĆofĆcut brackets (Fig. 11).

,*74(

(,*+62)&76 $40

(,*+62)&76 %4$&.(6

2&.176

'-756,1* 5&4(9

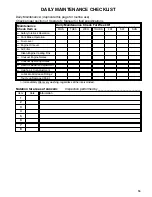

Loosen nut on gauge bar (Fig. 12) and set

adjusting screw to desired heightĆofĆcut. Distance

between bottom of screw head and face of bar is

heightĆofĆcut.

,*74(

$7*( %$4

(,*+6 $'-756,1* 5&4(9

76

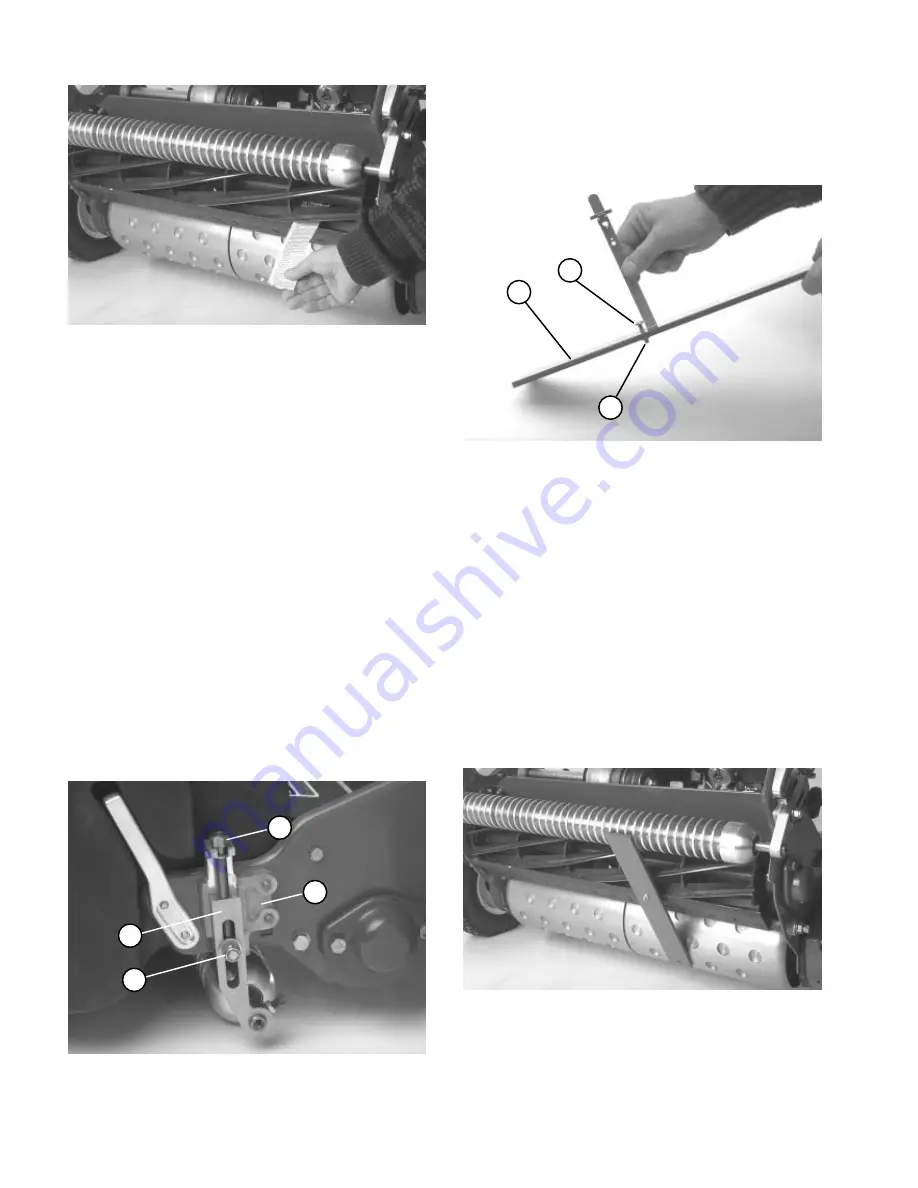

Hook screw head on cutting edge of bedknife and

rest rear end of bar on rear roller (Fig. 13).

Rotate adjusting screw until roller contacts front of

gauge bar. Adjust both ends of roller until entire roller is

parallel to the bedknife.

: When set properly, rear and front rollers

will contact gauge bar and screw will be snug against

bedknife. This assures heightĆofĆcut is identical at both

ends of bedknife.

,*74(

Tighten nuts to lock adjustment.

2 $82,' 5&$/3,1* 21 71'7/$6,1* 674)

0$.( 574( 42//(4 57332465 $4( 325,6,21(' 4($49$4'

42//(4 &/25(4 62 4((/