08354B DCN7877

Teledyne API T640 PM Mass Monitor

70

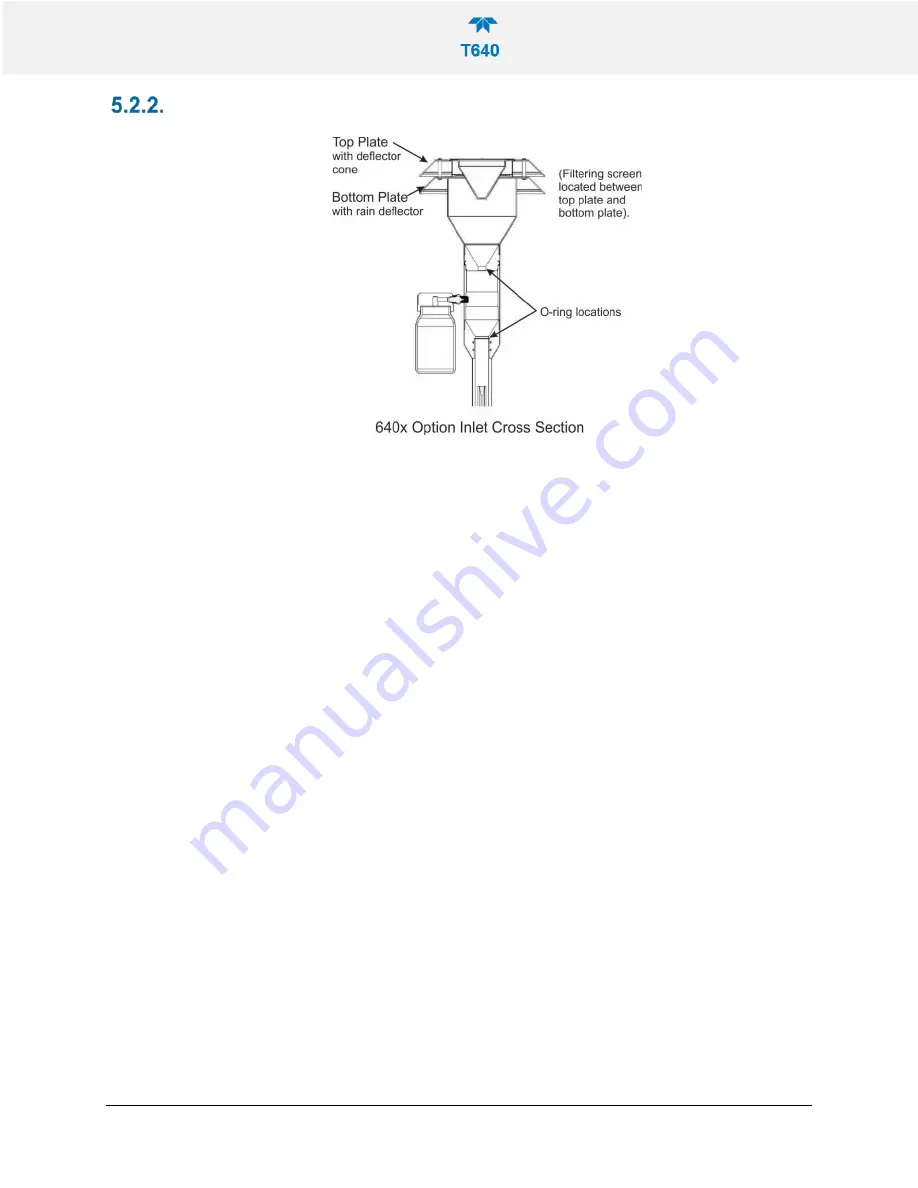

CLEANING THE US EPA PM10 INLET

Figure 5-2. 640X Option Disassembly

1. Power off the internal pump from the Setup>Vars>Pump Control menu. Pump

choices are ‘auto’, ‘off, and ‘cleaning cycle’. Press ‘edit’ and the ‘off’ to turn off

the internal pump. (Note: ‘cleaning cycle’ is a mode that pulses the internal

pump to help dislodge any obstructions between the optical cell and the

internal DFU).

2. Power off the bypass flow pump by unplugging it.

3. Remove the PM

10

sampling inlet from the downtube.

4. Disassemble the sampling inlet (four screws on the underside of inlet louvered

plates).

5. Carefully and thoroughly remove any dust deposits from inside the inlet.

6. Remove any insects or other debris from the filtering screen.

7. Unscrew the top of sampling inlet from the base of the inlet to expose the PM

10

well.

8. Using a moist lint free towel or wipe, clean the inside base of the PM10 well.

9. Using cotton tipped applicator (or similar) saturate the tip of the applicator with

DI water and clean out each of the three nozzles in the PM10 well.

10. Carefully inspect and remove any insects or spider webs. If there is a spider

web present, make note of it on the “Monthly QC and Maintenance Checklist”

sheet.

11. If needed, dry all components thoroughly with a clean cloth

12. Blow canned air through the three nozzles.

13. Inspect and clean, as necessary the bottom connection of the downtube with

a lint free towel or wipe.

14. Inspect and clean the water collector if any debris or water are present.

15. Check and, if needed, replace the O-rings located on the outside and the inside

of the base plate, and grease them with vacuum grease.