38

OUTBOARD TIMING

OUTBOARD TIMING. (STANDARD IGNITION)

. Follow

the step-by-step procedure outlined for timing outboard

engines with Standard ignition magnetos (non-solid

state).

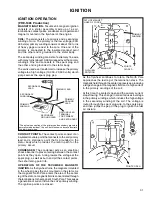

Apply a small amount of E.P. Lithium grease to the

contact area of the friction screw. Do not turn the

screw into the radius of the stator collar.

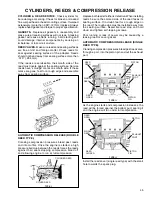

Install the stator with operating handle pointed in the

direction of the carburetor. Be sure the throttle post

is NOT INSIDE the arc of the throttle actuating cam.

Hold the throttle open when installing the stator.

Move the control lever to full retard, then move toward

full advance while tightening the friction screw until

the lever will not vibrate out of position when the engine

is running and yet can be easily rotated when speed

is adjusted.

Adjust ignition points to proper specification.

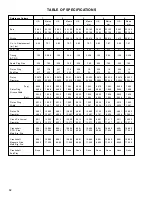

Remove leads from point terminal, then reinstall and

tighten the nut and washer. Attach a continuity device

to the point terminal post and to a good ground on

the engine as shown.

CONTACT

AREA OF

FRICTION

SCREW

T.D.C.

THROTTLE

POST

THROTTLE

ACTUATING

CAM

CONTROL

LEVER

FRICTION

SCREW

LEADS

REMOVED

POINT

TERMINAL POST

NUT AND WASHER

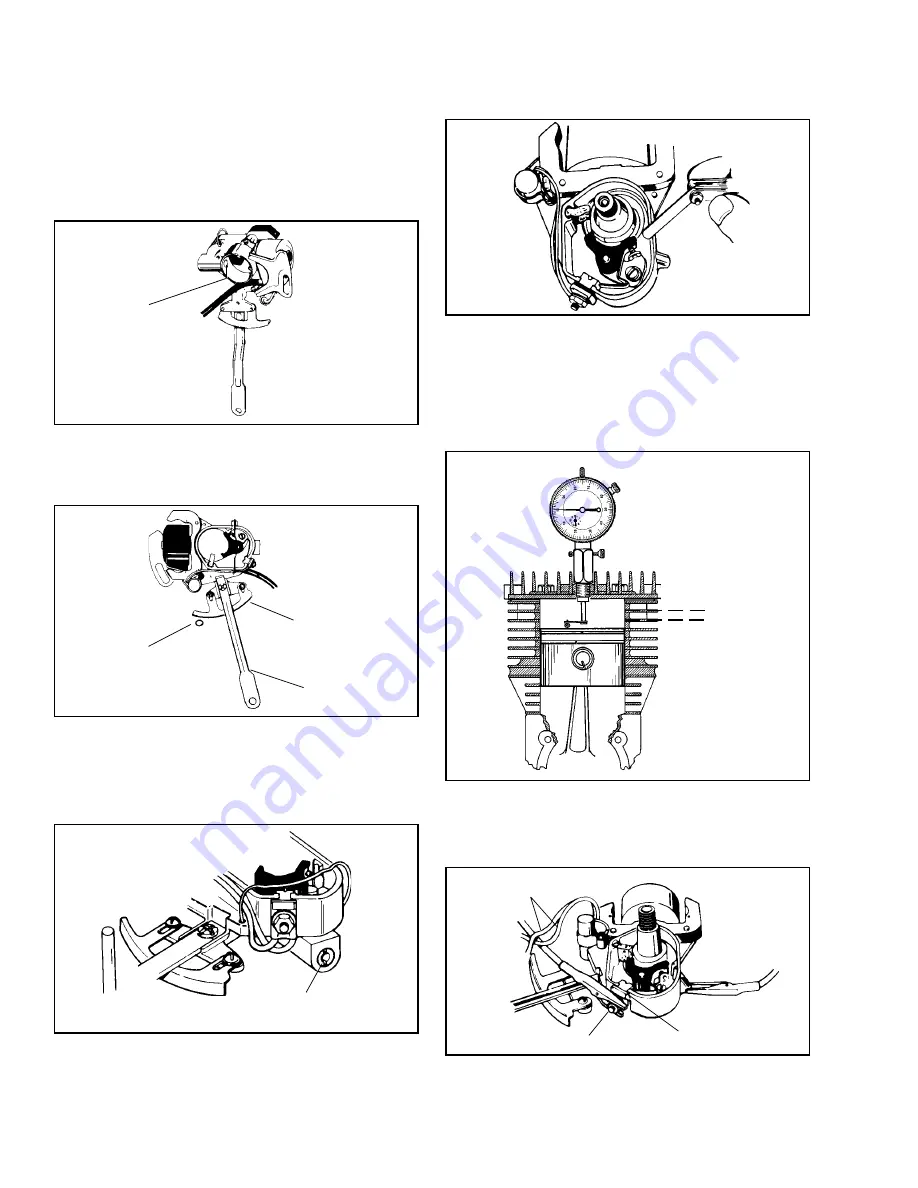

B.T.D.C.

Clean points by sliding lint free paper back and forth

between the contacts. Manually open points when

removing paper to eliminate paper fiber from remaining

between contacts.

Using a dial indicator, set the piston to the proper

Before-Top-Dead-Center (BTDC) to the specified

dimension.

Содержание AH520 -

Страница 67: ...64...