7

OPERATION

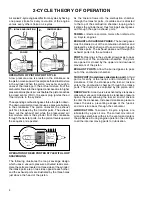

In the CHOKE or START position, the choke shutter

is closed, and the only air entering the engine enters

through openings around the shutter. As the engine

starts to rotate the downward piston travel will create

a low air pressure area in the engine cylinder above

the piston. Higher pressure (atmospheric air) rushes

into the engine to fill the created low pressure area.

Since the majority of the air passage is blocked by

the choke shutter, a relatively small quantity of air

enters the carburetor at increased speed. The main

nozzle and both idle fuel discharge ports are supplying

fuel due to the low air pressure in the intake of the

engine. A maximum fuel flow through the carburetor

orifices combined with the reduced quantity of air that

passes through the carburetor, make a very rich fuel

mixture which is needed to start a cold engine.

At engine IDLE speed, a relatively small amount of

fuel is required to operate the engine. The throttle is

almost completely closed. A fuel / air mixture is supplied

through the primary idle-fuel discharge orifice during

idle.

During INTERMEDIATE engine operation, a second

orifice is uncovered as the throttle shutter opens, and

more fuel mixture is allowed to atomize with the air

flowing into the engine.

During HIGH SPEED engine operation, the throttle

shutter is opened. Air flows through the carburetor

at high speed. The venturi, which decreases the size

of the air passage through the carburetor, further

accelerates the air flow. This high speed movement

of the air decreases the air pressure at the main nozzle

opening. Fuel is forced out the main nozzle opening

due the difference in the atmospheric air pressure

on the fuel in the carburetor bowl and the reduced

air pressure at the main nozzle opening.

CARBURETOR SERVICE.

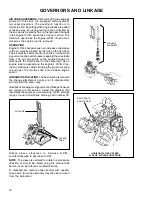

Carefully disassemble

carburetor, removing all non-metallic parts, i.e., gaskets,

viton seats and needles, O rings, fuel pump valves,

etc.

Nylon check balls used in some diaphragm carburetors

are not serviceable. Nylon can be damaged if subjected

to harsh cleaners for prolonged periods.

Remove the primer bulb (if equipped) by grasping with

a pliers and pulling and twisting out of the body. Remove

the retainer by prying and lifting out with a screwdriver.

Do not re-use old bulb or retainer.

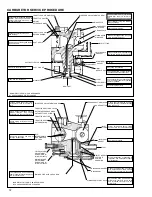

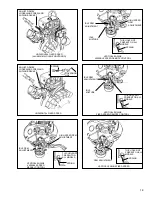

Remove all welch plugs if cleaning the carburetor. Secure

the carburetor in a vise equipped with protective jaws.

Use a small chisel sharpened to a 1/8" wide wedge

point. Drive the chisel into the plug to pierce the metal

and push down on the chisel to pry the plug out of the

hole.

Clean all metallic parts with solvent.

ABOUT 1/8" WIDE

WELCH PLUG

TO BE REMOVED

PRY OUT

PLUG

PIERCE PLUG WITH TIP

SMALL

CHISEL

DO NOT ALLOW CHISEL

POINT TO STRIKE

CARBURETOR BODY

OR CHANNEL REDUCER

SMALL CHISEL

NEW WELCH PLUG

SAME OR LARGER

DIAMETER OF PLUG

FLAT-END PUNCH

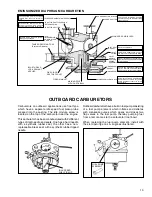

THROTTLE PLATE

THROTTLE LEVER

To install a new welch plug after cleaning, place welch

plug into receptacle with raised portion up. With a

punch equal to the size of the plug, merely flatten

the plug. Do not dent or drive the center plug below

the top surface of the carburetor. After installing the

welch plug, seal the outer diameter with finger nail

polish. (Do not use clear polish).

THROTTLE.

Examine the throttle lever and plate prior

to disassembly. Replace any worn and/or damaged

parts.

When reassembling, it is important that the lines on

the throttle plate are facing out when in the closed

position. Position throttle plates with the two lines at

12 and 3 oclock. If throttle plate has only one line,

the line should be positioned in the 12 oclock position.

If binding occurs, correct by loosening the screws

and repositioning the throttle plate.

Содержание AH520 -

Страница 67: ...64...