29

FLYWHEEL (INSIDE-EDGE) BRAKE SYSTEM

Tecumsehs brake systems provide two methods of

meeting compliance standards which has become a

Federal law as of June 30, 1982. There are two additional

methods used by equipment manufacturers that also

meet compliance standards, they are:

1. Use of the blade brake clutch in conjunction with

either a top or side mounted recoil starter. The blade

stops within three seconds after the operator lets

go of the blade control bail at the operator position

and the engine continues to run. Starter rope handle

is on the engine.

2. Use of a recoil starter (top or side mounted) with

the rope handle on the engine as opposed to within

24 inches from the operator position. This method

is acceptable if the mower deck passes the 360

degree foot probe test. A specified foot probe must

not contact the blade when applied completely around

the entire blade housing. This alternative can be

used with engine mounted brake systems and typical

bail controls. The blade stops within three seconds

after the operator lets go of the blade control bail

at the operator position and the engine is stopped.

Tecumsehs Flywheel (Inside-Edge) Brake System

provides consumer safety by shutting down the engine

and lawnmower blade within seconds after the operator

releases the Engine/Blade control at the handle of the

lawnmower.

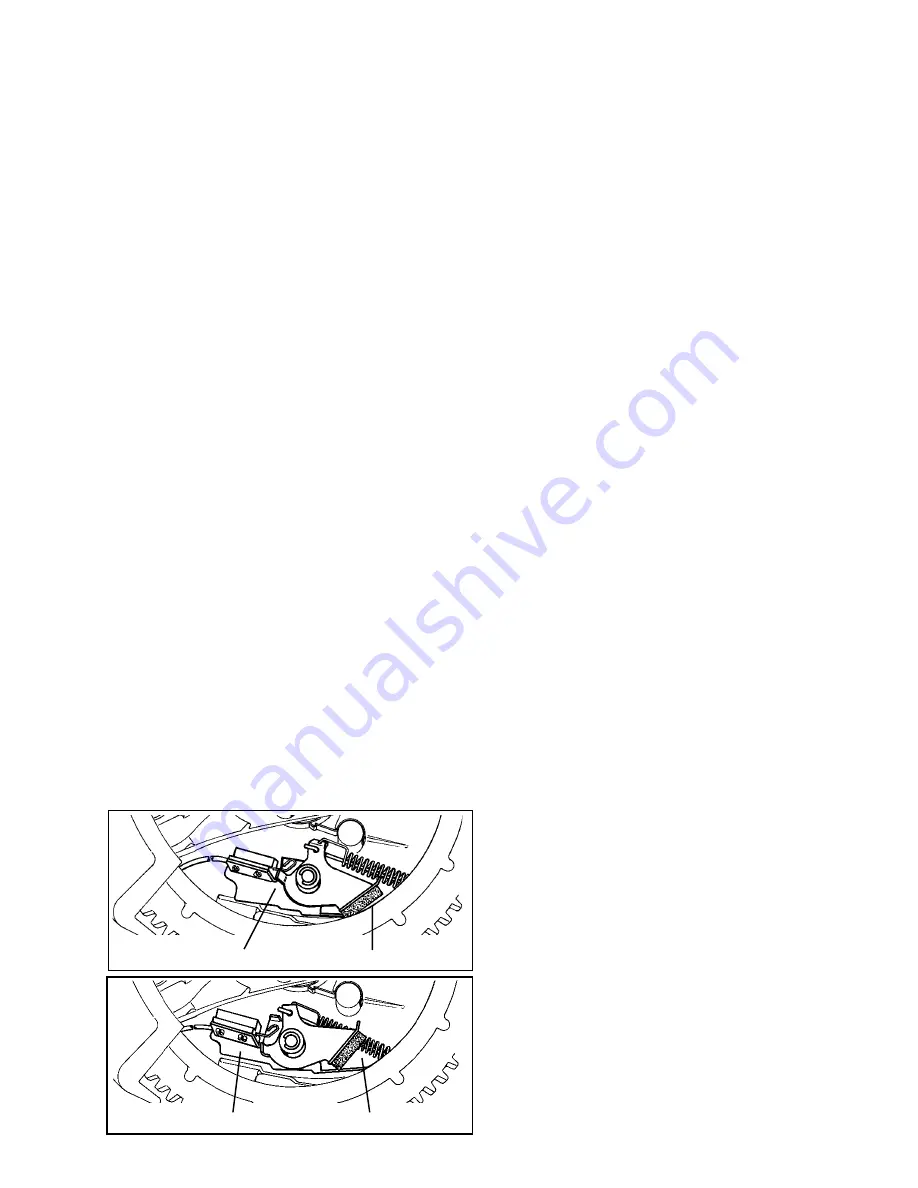

INSIDE EDGE SYSTEM

In the stop position the brake pad is applied to the

inside edge of the flywheel, at the same time the ignition

system is grounded.

In order to restart the engine, the brake control must

be applied. This action pulls the brake pad away from

the inside edge of the flywheel and opens the ignition

kill switch. On electric start systems the starter is

energized by an ignition switch or a two motion control.

On non-electric start systems, the recoil starter rope

must be pulled to start engine.

COMPONENTS

The Inside Edge system uses the following components:

The

brake lever and pad

assembly consists of a steel

lever with a brake pad bonded to the lever.

The

ignition kill switch

is a plastic block with a wire

extending out of it. The wire is attached to a terminal

which is connected to the ignition kill wire. The brake

lever contacts and grounds the wire of the switch when

the engine / blade control is released, and the ignition

module is grounded. This in turn kills the ignition.

The

interlock switch

is a push button switch that is

activated by the brake lever when the engine / blade

control is actuated. If there is a starter switch used

to start the engine, the interlock switch acts as a safety

switch and will not allow the starter to crank unless

the engine / blade control is depressed.

Where a two motion control is used the interlock switch

is utilized as the starter switch.

The

Torsion Spring

supplies the pressure to the brake

lever and brake pad to stop the flywheel.

The

Control Cable

transfers the motion of the

engine / blade control to the brake system.

SERVICE

If the brake system fails to kill the ignition and stop

the blade within 3 seconds the following service procedures

should be followed.

Remove the flywheel as outlined in "IGNITION" section.

NOTE:

BEFORE THE FLYWHEEL IS REMOVED OR

REPLACED, THE BRAKE PRESSURE ON THE

FLYWHEEL MUST BE RE-LEVELED AS OUTLINED.

BRAKE APPLIED

IGNITION SHORTED

BRAKE RELEASED

IGNITION OPEN

Содержание AH520 -

Страница 67: ...64...