8

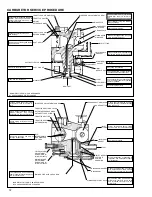

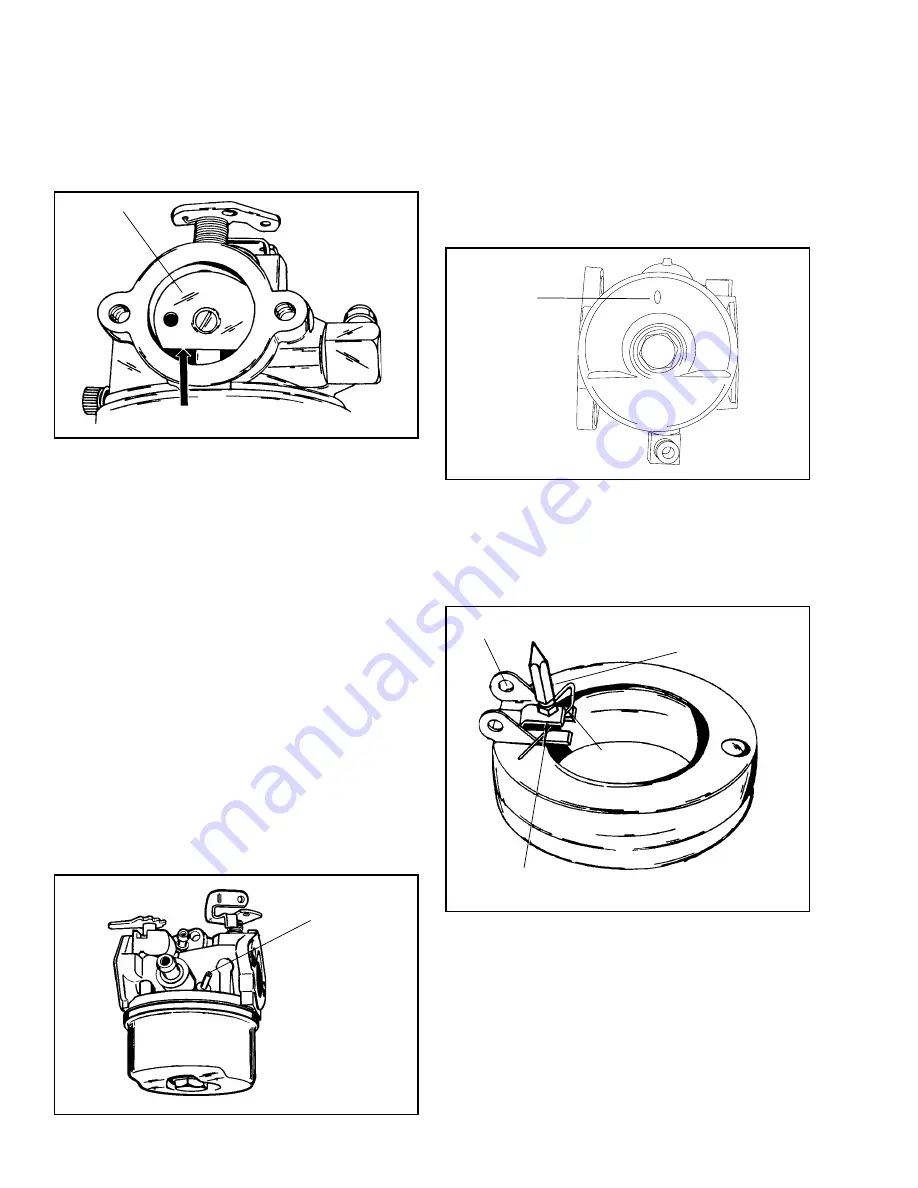

CHOKE.

Examine the choke lever and shaft at the

bearing points and holes into which the linkage is

fastened, and replace if worn or damaged. The choke

plate is inserted into the air horn of the carburetor in

such a position, that the flat side of the choke is down.

Before disassembly note the direction of choke plate

movement. Choke plates will operate in either direction.

Make sure it is assembled properly for your engine.

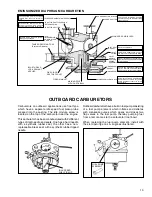

ADJUSTING SCREWS.

Remove the adjusting screws

from the carburetor body and examine the point, replace

the screws if damaged. Tension is maintained on the

screw with a coil spring. Examine and replace the

O ring seal(s) if damaged.

NOTE:

If screws are made of plastic, dip the end of

the screw in oil before installation to prevent damage.

FUEL BOWL RETAINING NUT.

The fuel bowl retaining

nut has a fixed main jet incorporated in the nut. This

small jet must be clean for proper fuel metering. Clean

by using compressed air.

DO NOT USE WIRE OR

HARD OBJECTS FOR CLEANING.

CARBURETOR VENTING.

Float-type carburetors must

have atmospheric air pressure acting against the fuel

in the fuel bowl. These vents can be external, with a

hole drilled through the side of the carburetor casting

or internal where atmospheric air is picked up in the

air horn near the air cleaner. Regardless of the type,

these vents must be clear and free from dirt, paint,

grease, etc.

HIGH TILT FLOAT STYLE

carburetors use an external

main air bleed.

FUEL BOWL.

The fuel bowl must be free of dirt and

corrosion. When disassembling a carburetor for repair,

always replace the fuel bowl O ring. Lubricate the

O ring with a small amount of oil for easier installation.

Install the float bowl by placing the detent portion

opposite of the hinge pin. Make sure the deepest end

of the bowl is opposite of the inlet needle. The bowl

has a small dimple located in the deepest part. The

purpose of this dimple is to minimize the chances of

the float sticking to the bottom of the bowl caused by

stale fuel.

CHOKE PLATE

DOWN TOWARD FUEL BOWL

MAIN AIR BLEED

FLOAT.

Remove the float by pulling out the float hinge

pin. Lift the float away from the carburetor body. This

will also lift the inlet needle out of the seat.

Examine the float for damage. Check the float hinge

bearing surfaces for wear, as well as the tab that contacts

the inlet needle. Replace any damaged or worn parts.

INLET NEEDLE

EXAMINE FLOAT HINGE FOR WEAR

AT BEARING SURFACES

INLET NEEDLE

CLIP

REMOVE FLOAT TO MAKE ADJUSTMENTS.

BEND THIS TAB TO ADJUST

DETENT

Float sticking can occur due to fuel deposits (gum or

varnish). This can be corrected by loosening the carburetor

bowl nut one full turn and rotating the bowl 1/4 turn in

either direction. Return the bowl to it's original position

and retighten the bowl nut.

Содержание AH520 -

Страница 67: ...64...