20

REWIND STARTERS

GENERAL INFORMATION

Rewind starters used on vertical shaft Tecumseh engines

are top mount horizontal pull style or side mount vertical

pull style. Horizontal shaft engines use side mounted

starters which can be mounted to pull either vertically

or horizontally. All rewind starters except the vertical

pull style turn the engine over by engaging a dog(s)

into the starter cup attached to the engine flywheel.

The vertical pull starter engages the starter gear into

the ring gear of the flywheel to turn the engine over.

All starters are spring loaded to retract the dog(s) or

starter gear when the engine speed exceeds the turning

speed of the starter.

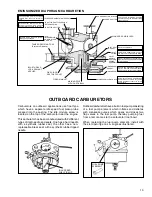

OPERATION

As the starter rope is pulled, the starter pulley rotates

on the center pin. The starter dog(s) is pinned or

pocketed in the pulley hub and extends outward when

the pulley's rotation forces the starter dog(s) to contact

the ears on the retainer. The retainer ears act as a

ramp to fully extend the starter dog(s). The fully extended

starter dog(s) locks in contact with notches in the

starter cup. When the engine fires and the rotational

speed of the starter cup exceeds the starter pulley,

the starter dog(s) disengages from the starter cup.

The starter dog spring(s) returns the starter dog(s)

to the disengaged position. The recoil spring turns the

starter pulley in the opposite direction, retracting the

starter rope until the handle contacts the stop.

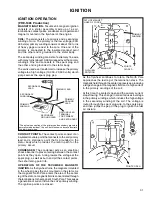

COMPONENTS

REWIND STARTERS, ELECTRIC STARTERS AND

ALTERNATORS

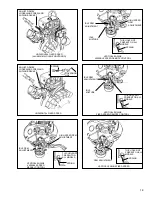

SERVICE

Starter related problems will require the starter to be

removed from the engine to diagnose the cause. Visually

inspect the starter dog(s), starter cup, retainer, springs,

rope, washers, and the starter pulley for wear or breakage.

Use one of the following procedures that applies to

your application, to disassemble, repair, and assemble

the starter. Always consult the Tecumseh Master Parts

Manual for the correct replacement parts.

ROPE SERVICE

Rope replacement should be done using the correct

part number replacement rope or braided rope of the

correct diameter and length. Consult the Tecumseh

Master Parts Manual to obtain the correct part number,

length, and size required. Use the following rope chart

to convert a numbered rope to a fractional diameter

for bulk rope use.

# 4 1/2 rope = 9/64" (3.572 mm) diameter

Part No. 730526 -100' (30.48 meters)

spool

# 5 rope

= 5/32" (3.964 mm) diameter

Part No. 730514 - 100' (30.48 meters)

spool

# 6 rope

= 3/16" (4.762 mm) diameter

Part No. 730516 - 100' (30.48 meters)

spool

Standard rope lengths

54" (16.5 meters) standard stamped steel starter

61" (18.6 meters) vertical pull - horizontal engagement

type

65" (20 meters)

vertical pull - vertical engagement

type

85" (26 meters)

extended handlebar rope start

(compliance)

Check the old rope for the right length for the application.

Some applications require longer lengths. The rope

ends should be cauterized by burning with a match

and wiping the rope end with a cloth while hot.

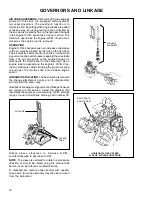

Rope replacement can be done without the starter being

disassembled on vertical pull starters that have "V"

notches in the bracket. Use the following procedure

for rope replacement.

1. Remove the starter assembly from the engine.

2. Turn the pulley until the staple in the pulley lines

up with the "V" notch. Pry out the staple with a

small screwdriver and remove the original rope.

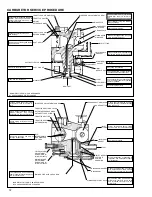

SPRING PIN

BRAKE SPRING

WASHER

WASHER

RETAINER

HANDLE

ROPE

STARTER HOUSING

PULLEY AND REWIND

SPRING ASSY.

STARTER DOG

DOG SPRING

Содержание AH520 -

Страница 67: ...64...